A maquiladora is a manufacturing operation in Mexico where factories import materials and equipment on a duty-free and tariff-free basis for assembly or manufacturing and then export the finished products. One prominent example of a maquiladora in manufacturing is the automotive industry, where companies like Ford and General Motors operate assembly plants near the U.S.-Mexico border. These maquiladoras assemble vehicle components such as engines, transmissions, and interior parts for export primarily to the United States. Electronics manufacturing is another key sector utilizing maquiladoras, with companies like Foxconn producing consumer electronics including smartphones and televisions. These factories leverage lower labor costs and proximity to the U.S. market to maintain competitive pricing and efficient supply chains. Data from Mexico's Instituto Nacional de Estadistica y Geografia (INEGI) shows maquiladoras contribute significantly to Mexico's GDP and export volume, highlighting their importance in the global manufacturing ecosystem.

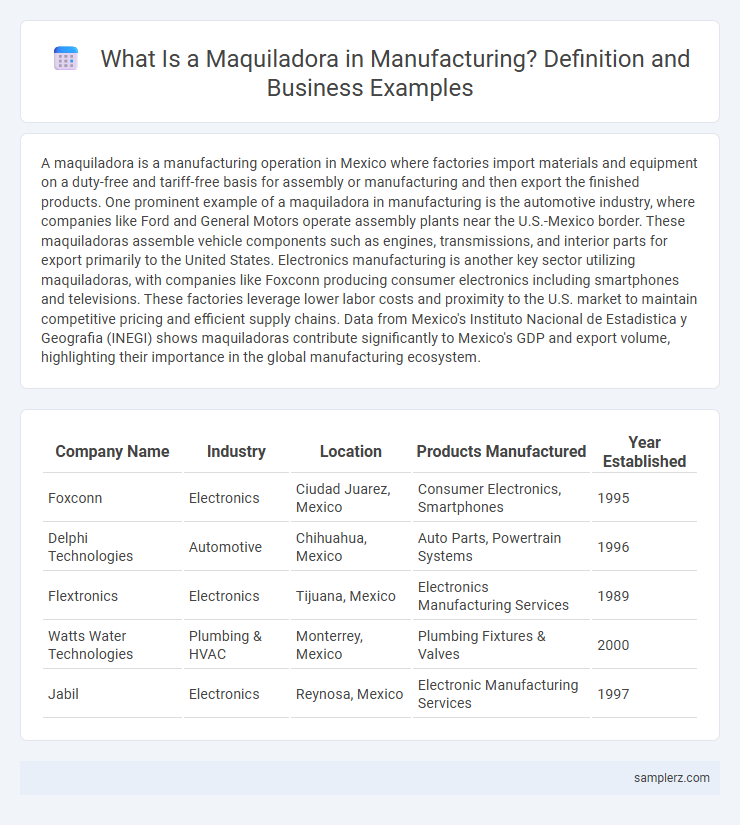

Table of Comparison

| Company Name | Industry | Location | Products Manufactured | Year Established |

|---|---|---|---|---|

| Foxconn | Electronics | Ciudad Juarez, Mexico | Consumer Electronics, Smartphones | 1995 |

| Delphi Technologies | Automotive | Chihuahua, Mexico | Auto Parts, Powertrain Systems | 1996 |

| Flextronics | Electronics | Tijuana, Mexico | Electronics Manufacturing Services | 1989 |

| Watts Water Technologies | Plumbing & HVAC | Monterrey, Mexico | Plumbing Fixtures & Valves | 2000 |

| Jabil | Electronics | Reynosa, Mexico | Electronic Manufacturing Services | 1997 |

Introduction to Maquiladoras in Manufacturing

Maquiladoras are manufacturing plants in Mexico that import materials and equipment duty-free for assembly or processing and then export the finished products, primarily to the United States. Prominent examples include companies like Foxconn and Delphi Automotive, which capitalize on cost-effective labor and proximity to North American markets. These facilities play a crucial role in cross-border trade, boosting manufacturing efficiency and economic growth through integrated supply chains.

Key Characteristics of Maquiladora Operations

Maquiladora operations in manufacturing are characterized by their location near the U.S.-Mexico border, allowing for duty-free import of raw materials and export of finished goods. These facilities emphasize labor-intensive assembly processes, benefiting from lower labor costs and flexible workforce arrangements. The integration of advanced logistics and just-in-time inventory systems ensures efficient cross-border supply chain management.

Historical Development of Maquiladoras in Mexico

Maquiladoras emerged in Mexico during the 1960s as a government initiative to boost industrial growth by attracting foreign investment through duty-free importation of raw materials. Key developments include the establishment of export processing zones near the U.S. border, facilitating significant growth in manufacturing sectors such as electronics, automotive, and textiles. Over time, maquiladoras have evolved into integral components of Mexico's export economy, contributing substantially to employment and trade balance.

Leading Maquiladora Companies in the Industry

Leading maquiladora companies in the manufacturing sector include Foxconn, known for assembling electronic products for major brands like Apple. Flex Ltd. specializes in advanced manufacturing solutions, serving industries from automotive to healthcare. Jabil Inc. demonstrates significant scale in contract manufacturing, producing complex components for electronics and consumer goods globally.

Automotive Sector: Maquiladora Case Studies

The automotive sector benefits significantly from maquiladora operations, with companies like Ford and General Motors establishing manufacturing plants along the U.S.-Mexico border to optimize production costs and supply chain efficiency. These maquiladoras specialize in assembling automotive parts, such as engines and transmissions, leveraging Mexico's skilled labor force and favorable trade agreements like USMCA. This model enables automakers to maintain global competitiveness by reducing tariffs and improving just-in-time delivery systems.

Electronics Manufacturing Through Maquiladoras

Electronics manufacturing through maquiladoras plays a crucial role in the North American supply chain, particularly in Mexico's border regions where companies like Foxconn and Flextronics operate large-scale plants. These maquiladoras specialize in producing consumer electronics, such as smartphones, televisions, and computer components, leveraging cost-efficient labor and favorable trade agreements like USMCA. The integration of advanced automation and skilled labor in maquiladoras boosts productivity while maintaining competitive pricing for global electronics brands.

Textile and Apparel Examples in Maquiladoras

Maquiladoras in the textile and apparel industry often include factories located in Mexico that specialize in assembling garments for export, such as those operated by major brands like Levi's and Gap. These manufacturing plants leverage lower labor costs and proximity to the U.S. market to produce denim, t-shirts, and outerwear efficiently. The maquiladora model supports high-volume production with just-in-time inventory systems, benefiting from favorable trade agreements like USMCA.

Advantages of the Maquiladora Model for Manufacturers

The maquiladora model offers manufacturers significant cost savings through lower labor expenses and duty-free importation of raw materials, enhancing profit margins. Proximity to the U.S. market enables faster turnaround times and improved supply chain efficiency, reducing inventory and transportation costs. This model also facilitates access to skilled labor and modern manufacturing infrastructure, fostering competitive production capabilities in global markets.

Challenges Faced by Maquiladora Facilities

Maquiladora facilities, such as those in Ciudad Juarez, face significant challenges including supply chain disruptions due to cross-border delays and strict customs regulations. Labor issues like wage disputes and workforce retention complications further impact operational efficiency. Environmental compliance and rising energy costs also add pressure to maintain profitability in competitive manufacturing sectors.

Future Trends for Maquiladoras in Global Manufacturing

Maquiladoras are increasingly adopting Industry 4.0 technologies such as automation, IoT, and AI to enhance production efficiency and reduce labor costs in global manufacturing. Nearshoring trends drive multinational corporations to relocate supply chains closer to the U.S. market, positioning Mexican maquiladoras as strategic hubs for faster delivery and lower tariffs. Sustainable manufacturing practices and digital transformation are also shaping the future, with maquiladoras integrating renewable energy and smart factory solutions to meet evolving environmental regulations and customer demands.

example of maquiladora in manufacturing Infographic

samplerz.com

samplerz.com