A maquiladora is a manufacturing operation in a free trade zone where factories import materials duty-free for assembly or processing before exporting finished products. One example of a maquiladora factory is a textile plant located in Ciudad Juarez, Mexico, where raw fabrics are imported from the United States, sewn into garments, and then exported back to U.S. retailers. This factory benefits from lower labor costs and favorable trade policies, increasing profitability and competitive advantage. The maquiladora system supports industries such as automotive, electronics, and apparel by enabling efficient cross-border supply chain operations. Data from Mexico's Instituto Nacional de Estadistica y Geografia (INEGI) shows that maquiladora exports account for more than 50% of the country's total manufactured exports. These factories create significant employment, with over one million workers employed in maquiladora operations across northern Mexico.

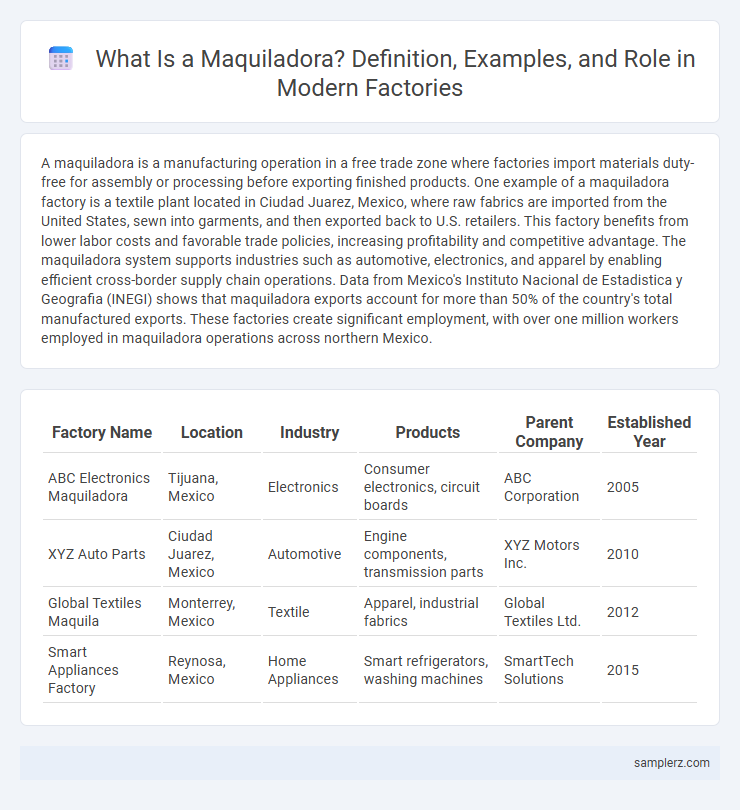

Table of Comparison

| Factory Name | Location | Industry | Products | Parent Company | Established Year |

|---|---|---|---|---|---|

| ABC Electronics Maquiladora | Tijuana, Mexico | Electronics | Consumer electronics, circuit boards | ABC Corporation | 2005 |

| XYZ Auto Parts | Ciudad Juarez, Mexico | Automotive | Engine components, transmission parts | XYZ Motors Inc. | 2010 |

| Global Textiles Maquila | Monterrey, Mexico | Textile | Apparel, industrial fabrics | Global Textiles Ltd. | 2012 |

| Smart Appliances Factory | Reynosa, Mexico | Home Appliances | Smart refrigerators, washing machines | SmartTech Solutions | 2015 |

Overview of Maquiladora Factories in Business

Maquiladora factories, primarily located along the US-Mexico border, operate as manufacturing plants that import materials and equipment duty-free for assembly or processing before exporting finished products. These factories play a crucial role in global supply chains by providing cost-effective labor and facilitating just-in-time production for industries such as electronics, automotive, and textiles. The maquiladora model enhances competitive advantage through reduced tariffs, streamlined logistics, and access to skilled yet affordable labor markets.

Key Features of a Maquiladora Operation

A maquiladora operation offers key features such as duty-free importation of raw materials and components for assembly or manufacturing, enabling cost-efficient production for export markets. These factories benefit from streamlined customs procedures and reduced tariffs, fostering competitiveness in international trade. Workforce utilization emphasizes skilled labor for assembly processes, with a focus on meeting strict quality standards and fast turnaround times.

Major Maquiladora Locations in Mexico

Major maquiladora locations in Mexico include the border cities of Tijuana, Ciudad Juarez, and Matamoros, which host numerous factories specializing in electronics, automotive parts, and medical devices. These cities benefit from proximity to the United States, skilled labor, and favorable trade agreements such as USMCA. Tijuana leads in electronics assembly, Ciudad Juarez focuses on automotive components, and Matamoros is a hub for heavy manufacturing and consumer goods production.

Benefits of Maquiladora Factories for Companies

Maquiladora factories, primarily located in Mexico, offer companies significant cost savings through lower labor expenses and favorable tax incentives. These factories enhance production efficiency by enabling firms to import raw materials duty-free and export finished goods with reduced tariffs under trade agreements like USMCA. The proximity to the U.S. market minimizes shipping times and logistics costs, boosting supply chain responsiveness and competitiveness.

Example: Electronics Manufacturing Maquiladora

An electronics manufacturing maquiladora in Mexico assembles consumer devices such as smartphones, televisions, and computer components, leveraging cost-effective labor and proximity to the U.S. market. These factories specialize in high-volume production with advanced automation and quality control systems to meet international standards. The maquiladora model enables global companies to optimize supply chain efficiency and reduce manufacturing expenses while maintaining rapid delivery timelines.

Example: Automotive Parts Production Maquiladora

The automotive parts production maquiladora in Ciudad Juarez exemplifies efficient cross-border manufacturing, specializing in components like brake systems and fuel injectors. This factory leverages Mexico's skilled labor force and proximity to U.S. markets, reducing logistics costs and delivery times for major automakers such as Ford and General Motors. High-tech assembly lines and stringent quality controls ensure compliance with international standards, enhancing competitiveness in the global automotive supply chain.

Example: Textile and Apparel Maquiladora

A prominent example of a textile and apparel maquiladora is the Juarez Industrial Park in Mexico, where factories specialize in producing garments for major global brands. These maquiladoras benefit from advantageous trade agreements and lower labor costs, enabling efficient fabrication of textiles for export to the U.S. and other markets. Advanced machinery and skilled workers contribute to high-quality apparel production while maintaining competitive pricing and rapid turnaround times.

Example: Medical Device Maquiladora

A medical device maquiladora in Mexico specializes in assembling high-precision components such as surgical instruments and diagnostic equipment for export to the U.S. market. These factories benefit from advanced automation technologies and skilled labor to maintain strict quality control and compliance with FDA regulations. Leveraging duty-free raw materials and proximity to medical hubs enhances supply chain efficiency and reduces lead times.

Supply Chain Impact of Maquiladora Factories

Maquiladora factories, such as those in Ciudad Juarez, significantly enhance supply chain efficiency by enabling nearshore manufacturing and assembly for U.S.-based companies. These factories reduce lead times and transportation costs by situating production close to key markets while leveraging low labor costs and favorable trade agreements like USMCA. The integration of maquiladoras into global supply chains improves inventory management, responsiveness to market demand, and overall competitiveness for multinational corporations.

Challenges Facing Maquiladora Factories Today

Maquiladora factories face significant challenges such as fluctuating labor costs, supply chain disruptions, and increasing regulatory scrutiny from both Mexican and U.S. governments. Rising demand for sustainable practices pressures these plants to adopt costly environmental controls and labor standards compliance. Moreover, geopolitical tensions impact tariff policies, complicating cross-border trade and profitability for maquiladoras in regions like Ciudad Juarez and Tijuana.

example of maquiladora in factory Infographic

samplerz.com

samplerz.com