Pick-pack is a critical process in business logistics where products are selected and packed for shipment to customers. For example, an e-commerce company receives multiple orders daily and uses a pick-pack system to efficiently locate items in their warehouse and prepare them for delivery. This method reduces errors and speeds up order fulfillment, enhancing customer satisfaction and operational efficiency. In retail businesses, the pick-pack process involves retrieving products from inventory based on specific order requirements and packaging them securely. Data from inventory management systems guide workers to the exact location of items, minimizing time spent searching. The integration of barcode scanners and automated systems in pick-pack operations ensures accurate tracking and helps maintain real-time inventory data.

Table of Comparison

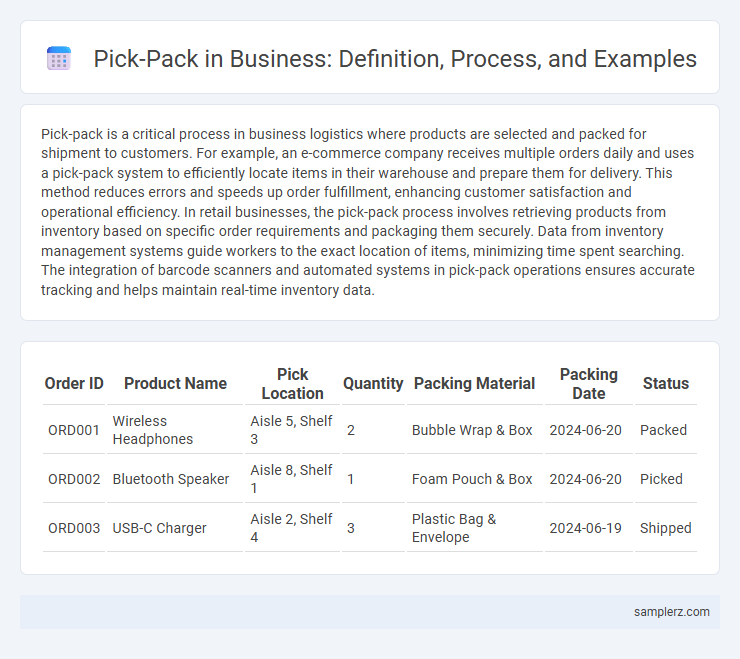

| Order ID | Product Name | Pick Location | Quantity | Packing Material | Packing Date | Status |

|---|---|---|---|---|---|---|

| ORD001 | Wireless Headphones | Aisle 5, Shelf 3 | 2 | Bubble Wrap & Box | 2024-06-20 | Packed |

| ORD002 | Bluetooth Speaker | Aisle 8, Shelf 1 | 1 | Foam Pouch & Box | 2024-06-20 | Picked |

| ORD003 | USB-C Charger | Aisle 2, Shelf 4 | 3 | Plastic Bag & Envelope | 2024-06-19 | Shipped |

Introduction to Pick-Pack Processes in Business

Pick-pack processes in business involve selecting products from inventory and packaging them for shipment, optimizing order fulfillment efficiency. Effective pick-pack systems utilize technology such as barcode scanners and warehouse management software to reduce errors and speed up operations. Streamlined pick-pack workflows enhance customer satisfaction by ensuring accurate and timely delivery of orders.

Understanding the Pick-Pack Workflow

The pick-pack workflow in business involves selecting products from inventory (pick) and preparing them for shipment (pack), ensuring accuracy and efficiency in order fulfillment. Effective pick-pack processes rely on inventory management systems, barcode scanning, and real-time tracking to minimize errors and reduce processing time. This workflow is critical in e-commerce and retail sectors where timely delivery and order accuracy directly impact customer satisfaction and operational costs.

Key Benefits of Implementing Pick-Pack Systems

Implementing pick-pack systems in e-commerce businesses significantly reduces order processing time and minimizes errors, enhancing customer satisfaction and operational efficiency. These systems streamline inventory management by improving accuracy in picking and packing, which lowers labor costs and decreases product returns. Real-time data integration within pick-pack processes also boosts supply chain visibility and supports faster decision-making in fulfillment operations.

Common Pick-Pack Strategies in Modern Warehousing

Common pick-pack strategies in modern warehousing include zone picking, where workers are assigned specific areas to fulfill orders, and wave picking, which organizes tasks based on delivery schedules or shipping priorities. Batch picking optimizes efficiency by grouping multiple orders with similar items, reducing travel time inside the warehouse. Implementing automated systems and barcode scanning enhances accuracy and speed in the pick-pack process, contributing to streamlined inventory management and faster order fulfillment.

Real-World Pick-Pack Examples in E-Commerce

Real-world pick-pack examples in e-commerce include Amazon's fulfillment centers, where automated systems and human workers collaborate to efficiently select and package products for shipping. Shopify-powered stores often use integrated inventory management software to streamline pick-pack processes, reducing errors and speeding up order fulfillment. Another example is Walmart's distribution network, which employs advanced robotics and real-time data tracking to optimize pick-pack accuracy and delivery speed.

Technologies Enhancing Pick-Pack Efficiency

Automated conveyor systems and robotic arms significantly increase pick-pack efficiency by reducing human error and speeding up order processing in warehouses. Barcode scanners and RFID technology ensure accurate item identification and inventory tracking, streamlining the picking process. Advanced warehouse management software integrates real-time data to optimize routing and resource allocation, maximizing productivity.

Pick-Pack Automation: Case Studies and Success Stories

Pick-pack automation in business is exemplified by Amazon's fulfillment centers, where robots and AI systems streamline sorting, packing, and shipping processes to boost efficiency and accuracy. Ocado Technology employs advanced pick-pack automation solutions to manage grocery orders with minimal human intervention, enhancing speed and reducing errors. DHL's automated warehouses demonstrate significant improvements in order fulfillment times and cost reductions through integrated pick-pack robotics and intelligent software systems.

Challenges Faced in Pick-Pack Operations

Pick-pack operations in business often encounter challenges such as inaccurate inventory management, leading to order fulfillment errors and delays. Space constraints in warehouses can disrupt efficient item picking, impacting overall productivity and customer satisfaction. Labor shortages and high turnover rates further complicate maintaining consistent pick-pack accuracy and speed.

Best Practices for Optimizing Pick-Pack Procedures

Effective pick-pack procedures enhance order accuracy and reduce fulfillment time by implementing zone picking and batch processing strategies. Utilizing barcode scanners and real-time inventory management software minimizes errors and ensures seamless workflow integration. Regular employee training and ergonomic workstation design contribute to productivity and decrease operational costs in warehouse environments.

Future Trends in Pick-Pack Solutions for Businesses

Future trends in pick-pack solutions for businesses emphasize automation and AI integration, enhancing efficiency and accuracy in order fulfillment. Robotics and smart sorting systems reduce labor costs and turnaround times, while real-time inventory tracking and data analytics optimize supply chain management. Companies adopting these technologies gain competitive advantages through faster delivery and improved customer satisfaction.

example of pick-pack in business Infographic

samplerz.com

samplerz.com