A maquiladora is a manufacturing operation in Mexico where factories import raw materials and equipment duty-free for assembly or manufacturing and then export the finished products. These factories are typically owned by foreign companies, especially from the United States, to leverage lower labor costs and favorable trade agreements like USMCA. The maquiladora system significantly contributes to Mexico's export economy, particularly in industries such as electronics, automotive, and textiles. One prominent example of a maquiladora in business is the automotive industry, where companies like General Motors and Ford operate plants in northern Mexican cities such as Ciudad Juarez and Monterrey. These facilities import auto parts, assemble vehicles, and then export them primarily to the U.S. market. The maquiladora model enables these companies to reduce production costs while maintaining close proximity to their primary consumer base, enhancing supply chain efficiency.

Table of Comparison

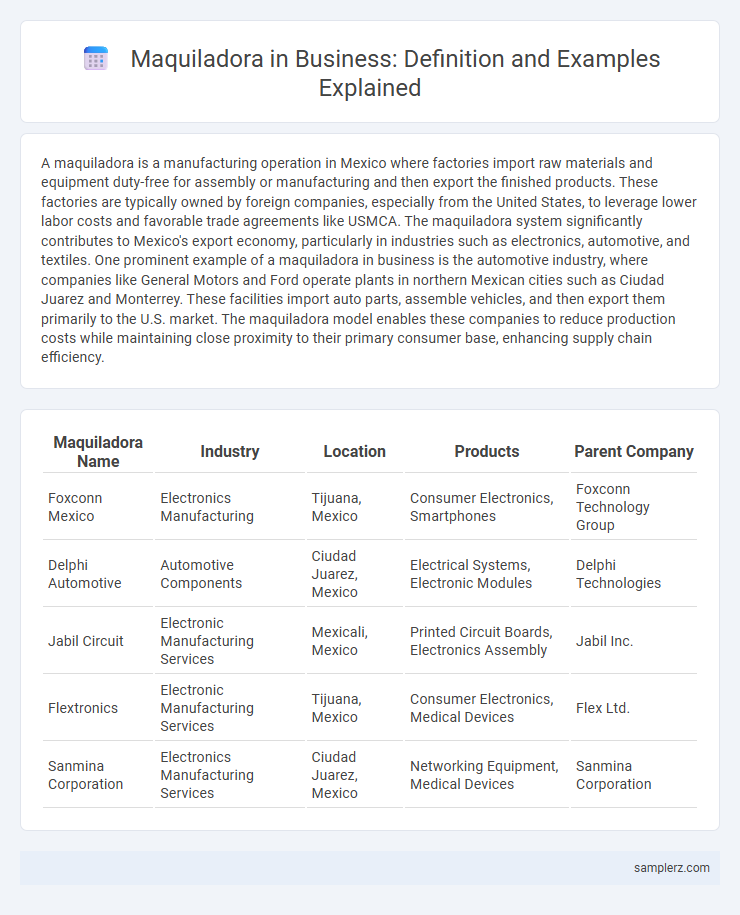

| Maquiladora Name | Industry | Location | Products | Parent Company |

|---|---|---|---|---|

| Foxconn Mexico | Electronics Manufacturing | Tijuana, Mexico | Consumer Electronics, Smartphones | Foxconn Technology Group |

| Delphi Automotive | Automotive Components | Ciudad Juarez, Mexico | Electrical Systems, Electronic Modules | Delphi Technologies |

| Jabil Circuit | Electronic Manufacturing Services | Mexicali, Mexico | Printed Circuit Boards, Electronics Assembly | Jabil Inc. |

| Flextronics | Electronic Manufacturing Services | Tijuana, Mexico | Consumer Electronics, Medical Devices | Flex Ltd. |

| Sanmina Corporation | Electronics Manufacturing Services | Ciudad Juarez, Mexico | Networking Equipment, Medical Devices | Sanmina Corporation |

Introduction to Maquiladoras in Business

Maquiladoras are manufacturing plants often located in Mexico near the U.S. border, where companies import raw materials duty-free, assemble products, and export finished goods. These factories enable businesses to reduce production costs through lower labor expenses and favorable trade policies under agreements like USMCA. Prominent examples include automobile assembly plants operated by companies such as Ford and General Motors, which capitalize on maquiladora benefits to enhance supply chain efficiency and competitiveness.

Key Characteristics of Maquiladora Operations

Maquiladora operations typically involve manufacturing plants located near the U.S.-Mexico border that import raw materials duty-free for assembly, processing, or fabrication before exporting finished goods back to the U.S. These plants emphasize labor-intensive production, cost efficiency, and quick turnaround times to serve North American markets. Key characteristics include preferential tariff treatment, reliance on cross-border supply chains, and integration with global trade agreements such as NAFTA or USMCA.

Notable Maquiladora Companies and Their Impact

Notable maquiladora companies such as Foxconn, Delphi Technologies, and Lear Corporation have significantly contributed to the growth of the manufacturing sector in Mexico, boosting employment and export volumes. Foxconn, a major electronics manufacturer, operates extensive facilities producing components for leading global brands like Apple, impacting both local economies and international supply chains. Delphi Technologies and Lear Corporation enhance automotive production capabilities, reinforcing Mexico's position as a critical hub for North American automotive manufacturing and fostering industrial development.

Case Study: Automotive Maquiladoras in Mexico

Automotive maquiladoras in Mexico serve as prime examples of successful cross-border manufacturing, leveraging low labor costs and proximity to the U.S. market. Companies like Ford, General Motors, and Volkswagen operate extensive assembly plants in states such as Baja California and Nuevo Leon, producing parts and vehicles for both domestic and international distribution. This maquiladora model enhances supply chain efficiency, reduces tariffs through NAFTA/USMCA agreements, and drives economic growth in Mexican industrial hubs.

Electronics Industry: Leading Maquiladora Examples

Foxconn Technology Group stands as a premier example of a maquiladora in the electronics industry, assembling products for major brands like Apple and Sony. Its manufacturing plants in Mexico leverage skilled labor and favorable trade agreements to produce high-quality electronic components and devices efficiently. This model highlights the integration of global supply chains with local production advantages in the maquiladora system.

Benefits of Maquiladora Business Models

Maquiladora business models offer significant cost advantages by leveraging lower labor expenses in Mexico, enhancing profit margins for U.S. and global companies. These operations benefit from tariff exemptions under agreements like the USMCA, enabling duty-free import and export of goods. The strategic location near the U.S. border facilitates just-in-time manufacturing, reducing lead times and inventory costs for businesses.

Challenges Faced by Maquiladoras

Maquiladoras, such as those in the Mexican border regions, face challenges including fluctuating labor costs, supply chain disruptions, and stringent regulatory compliance requirements from both Mexican and U.S. governments. High dependence on just-in-time inventory systems exposes these factories to risks from transportation delays and trade policy changes. Additionally, navigating environmental regulations and labor rights concerns requires continuous adaptation and investment in sustainable practices.

Regulatory Framework Governing Maquiladoras

Maquiladoras operate under a specific regulatory framework designed to promote foreign investment and export-oriented manufacturing by offering tax incentives, simplified import-export procedures, and relaxed labor regulations, particularly in Mexico. The IMMEX program governs most maquiladoras, allowing temporary importation of materials duty-free for assembly or manufacturing before export. Compliance with environmental, labor, and customs regulations is mandatory to maintain eligibility and optimize operational efficiency within this framework.

Maquiladoras and Supply Chain Efficiency

Maquiladoras, such as those operated by companies like Foxconn in Mexico, play a pivotal role in enhancing supply chain efficiency by leveraging cost-effective labor and proximity to the US market. These factories enable just-in-time manufacturing, reducing lead times and inventory costs for electronics and automotive industries. Integrating maquiladoras into supply chains supports expedited production cycles and streamlined cross-border logistics, driving competitive advantages in global trade.

Future Trends in Maquiladora Business Practices

Future trends in maquiladora business practices emphasize automation, digital supply chain integration, and sustainability improvements. Companies are increasingly investing in Industry 4.0 technologies such as IoT, AI-powered production monitoring, and robotics to boost efficiency and reduce costs. Environmental regulations and corporate social responsibility drive maquiladoras to adopt green manufacturing processes and energy-efficient solutions.

example of maquiladora in business Infographic

samplerz.com

samplerz.com