Radio Frequency Identification (RFID) is widely used in inventory management to track products and assets in real-time. Retailers embed RFID tags on merchandise, enabling automated scanning and accurate stock level monitoring without manual barcode scanning. Data collected through RFID systems helps reduce inventory discrepancies and improve supply chain efficiency. Warehouse operations benefit from RFID technology by streamlining the process of locating and managing inventory items. RFID readers capture data from tagged goods as they move through receiving, storage, and shipping stages, providing detailed insights into stock movement. This technology enhances data accuracy, minimizes human error, and accelerates inventory audits.

Table of Comparison

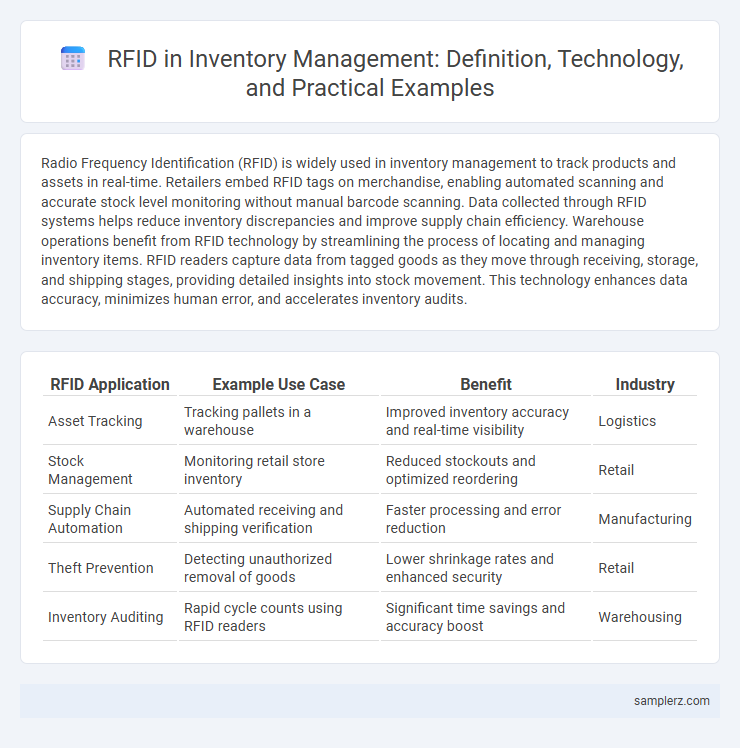

| RFID Application | Example Use Case | Benefit | Industry |

|---|---|---|---|

| Asset Tracking | Tracking pallets in a warehouse | Improved inventory accuracy and real-time visibility | Logistics |

| Stock Management | Monitoring retail store inventory | Reduced stockouts and optimized reordering | Retail |

| Supply Chain Automation | Automated receiving and shipping verification | Faster processing and error reduction | Manufacturing |

| Theft Prevention | Detecting unauthorized removal of goods | Lower shrinkage rates and enhanced security | Retail |

| Inventory Auditing | Rapid cycle counts using RFID readers | Significant time savings and accuracy boost | Warehousing |

Introduction to RFID Technology in Inventory Management

RFID technology revolutionizes inventory management by using radio frequency identification tags to automatically track and identify products in real time, enhancing accuracy and efficiency. Businesses leverage RFID systems to reduce manual counting errors, prevent stockouts, and improve supply chain transparency. Implementing RFID enables seamless inventory monitoring, faster asset recovery, and optimized stock levels across warehouses and retail environments.

Key Benefits of RFID for Inventory Control

RFID technology enhances inventory control by enabling real-time tracking of stock levels, reducing human error, and minimizing inventory shrinkage. Automated data capture through RFID tags improves accuracy and speeds up inventory audits, leading to optimized stock management and reduced carrying costs. The enhanced visibility provided by RFID systems supports better demand forecasting and streamlined supply chain operations.

Real-World Examples of RFID in Retail Inventory

RFID technology is widely used by retail giants like Walmart and Zara to enhance inventory accuracy and streamline stock management. By embedding RFID tags in products, these retailers achieve real-time inventory tracking, reducing stockouts and overstock situations. This implementation significantly improves supply chain efficiency and customer satisfaction in the retail sector.

RFID Integration in Warehouse Management Systems

RFID integration in warehouse management systems enhances inventory accuracy by enabling real-time tracking of goods throughout the supply chain. This technology automates data capture, reducing labor costs and minimizing human errors during stock taking and product dispatch. Implementation of RFID tags and readers streamlines warehouse operations, improves asset visibility, and accelerates order fulfillment processes.

Case Study: RFID Use in Automotive Inventory Tracking

RFID technology enhances automotive inventory tracking by providing real-time visibility of parts and finished vehicles throughout the supply chain. In a case study involving a major automotive manufacturer, RFID tags attached to components reduced inventory errors by 30% and improved production line efficiency by 25%. The system enables automated data capture, minimizes manual scanning, and accelerates stock audits, leading to reduced downtime and optimized warehouse management.

How Logistics Companies Use RFID to Manage Stock

Logistics companies use RFID technology to track inventory in real-time, reducing errors and improving accuracy in stock management. By attaching RFID tags to products, they enable automated scanning and instant data capture during transportation and warehousing processes. This streamlined approach enhances supply chain visibility and optimizes stock levels, minimizing delays and shortages.

RFID Applications in Pharmaceutical Inventory

RFID technology enhances pharmaceutical inventory management by enabling real-time tracking of medication batches, expiration dates, and storage conditions. This system minimizes human error and ensures regulatory compliance by automating inventory audits and reducing counterfeit drug risks. Integrating RFID in pharmaceutical supply chains improves accuracy, safety, and operational efficiency.

RFID-Enabled Smart Shelves for Inventory Accuracy

RFID-enabled smart shelves revolutionize inventory accuracy by providing real-time tracking of products through embedded RFID tags and readers. These shelves automatically scan items as they are placed or removed, minimizing human error and inventory discrepancies. Retailers leverage this technology to enhance stock management, reduce shrinkage, and improve replenishment efficiency.

Reducing Inventory Shrinkage with RFID Solutions

RFID technology significantly reduces inventory shrinkage by enabling real-time asset tracking and automated stock audits, minimizing human errors and theft. Retailers using RFID systems report shrinkage reductions of up to 30% due to precise item-level visibility across warehouses and stores. The integration of RFID solutions enhances inventory accuracy and streamlines loss prevention strategies in supply chain management.

Future Trends: RFID and IoT in Inventory Management

RFID technology combined with IoT sensors is revolutionizing inventory management by enabling real-time tracking and automated stock replenishment across warehouses. Advanced IoT-enabled RFID tags provide granular data analytics on product location, condition, and movement, enhancing supply chain visibility and reducing shrinkage. Future trends indicate widespread adoption of AI-driven RFID-IoT systems to optimize inventory accuracy and predictive maintenance in smart warehouses.

example of RFID in inventory Infographic

samplerz.com

samplerz.com