Piezoelectric actuators utilize the piezoelectric effect to convert electrical energy into precise mechanical motion, making them essential in high-precision applications. These actuators are commonly found in inkjet printers, where piezoelectric crystals control the ejection of ink droplets with exceptional accuracy. The ability of the piezoelectric material to rapidly expand and contract under an electric field enables fine positional control in micro-scale movements. In robotics, piezoelectric actuators provide accurate actuation for small-scale mechanisms, such as in micro-robotic joints or vibration control systems. Their high responsiveness and stability under varying temperatures make them suitable for aerospace and medical devices, where exact motion control is critical. Data from performance tests show piezoelectric actuators achieving nanometer-level precision, highlighting their effectiveness in cutting-edge technological applications.

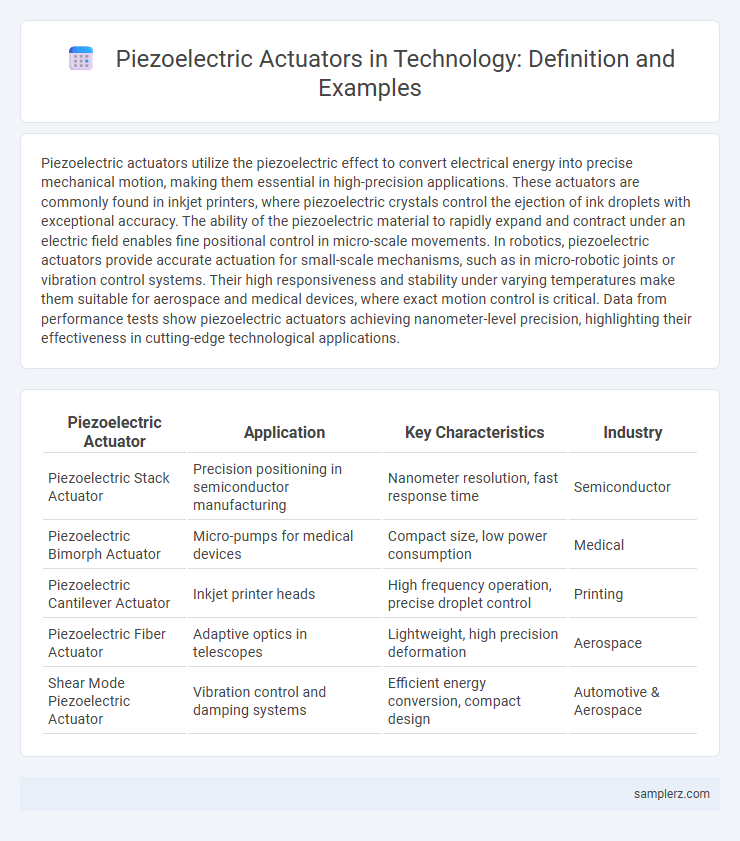

Table of Comparison

| Piezoelectric Actuator | Application | Key Characteristics | Industry |

|---|---|---|---|

| Piezoelectric Stack Actuator | Precision positioning in semiconductor manufacturing | Nanometer resolution, fast response time | Semiconductor |

| Piezoelectric Bimorph Actuator | Micro-pumps for medical devices | Compact size, low power consumption | Medical |

| Piezoelectric Cantilever Actuator | Inkjet printer heads | High frequency operation, precise droplet control | Printing |

| Piezoelectric Fiber Actuator | Adaptive optics in telescopes | Lightweight, high precision deformation | Aerospace |

| Shear Mode Piezoelectric Actuator | Vibration control and damping systems | Efficient energy conversion, compact design | Automotive & Aerospace |

Introduction to Piezoelectric Actuators

Piezoelectric actuators convert electrical energy into precise mechanical displacement using materials such as quartz or lead zirconate titanate (PZT), enabling applications in micro-positioning and optical devices. Their ability to generate rapid, accurate movements with high force density makes them essential components in precision engineering and robotics. Advances in piezoelectric actuator technology have expanded their use in medical ultrasound equipment, inkjet printers, and vibration control systems.

Core Principles of Piezoelectricity in Actuators

Piezoelectric actuators operate based on the direct conversion of electrical energy into mechanical displacement through the deformation of piezoelectric crystals under an applied electric field. These actuators exploit the core principle where certain materials produce a strain proportional to the voltage, enabling precise positioning in applications like precision optics and microelectromechanical systems (MEMS). The intrinsic coupling between electrical and mechanical domains in piezoelectric ceramics ensures high responsiveness and durability, making them essential in ultra-fine actuation tasks.

Advantages of Piezoelectric Actuators in Modern Technology

Piezoelectric actuators enable ultra-precise motion control with nanometer-scale accuracy, making them essential for applications in semiconductor manufacturing and optical device alignment. Their rapid response times and high force-to-volume ratios outperform traditional electromagnetic actuators in compact systems such as micro-robotics and precision instrumentation. Moreover, piezoelectric actuators offer excellent energy efficiency and minimal electromagnetic interference, enhancing reliability in sensitive environments like medical imaging and aerospace engineering.

Common Applications of Piezoelectric Actuators

Piezoelectric actuators are widely used in precision positioning systems, such as in optical devices and semiconductor manufacturing equipment, due to their high accuracy and fast response times. They are also common in inkjet printer heads, where they control the ejection of ink droplets with micro-scale precision. Furthermore, piezoelectric actuators play a crucial role in medical ultrasound imaging, enabling fine control of transducer elements for better image resolution.

Linear Piezoelectric Actuator Examples

Linear piezoelectric actuators are extensively used in precision positioning applications such as nanopositioning stages, adaptive optics, and scanning probe microscopy. Examples include shear-mode piezo stacks for fine lateral displacement, unimorph actuators in inkjet printers for droplet ejection, and multilayer piezoelectric actuators in fuel injection systems for automotive engines. These actuators convert electrical signals directly into controlled linear motion with nanometer resolution and rapid response times.

Rotational Piezoelectric Actuators: Use Cases

Rotational piezoelectric actuators are widely used in precision positioning systems, such as in optical instruments for fine angular adjustments. These actuators enable smooth, high-resolution rotation in applications like camera lens focusing and aerospace control surfaces. Their high torque density and rapid response make them ideal for micro-robotics and semiconductor wafer alignment tasks.

Precision Positioning with Piezoelectric Devices

Piezoelectric actuators enable ultra-precise positioning with nanometer-scale accuracy, making them ideal for applications in microscopy, semiconductor manufacturing, and optical alignment. Their rapid response times and high resolution allow for exact control in micro- and nano-positioning tasks, improving the performance of precision instruments. These devices convert electrical signals directly into mechanical displacement, ensuring reliable and stable movement in high-precision environments.

Piezoelectric Actuators in Medical Devices

Piezoelectric actuators are integral to medical devices, offering precise control and rapid response in applications such as ultrasound imaging and drug delivery systems. These actuators convert electrical signals into mechanical movement with high accuracy, enhancing the performance of surgical tools and implantable pumps. Their compact size and energy efficiency make them ideal for minimally invasive procedures and wearable health monitors.

Industrial Automation Powered by Piezoelectric Actuation

Piezoelectric actuators in industrial automation provide precise, rapid motion control essential for high-speed manufacturing processes and robotic assembly lines. Their ability to convert electrical signals into mechanical movement with nanometer resolution enhances the accuracy of tasks such as micro-positioning and vibration control. Industries benefit from improved efficiency and reduced maintenance costs due to the solid-state reliability and minimal wear of piezoelectric-based systems.

Emerging Trends in Piezoelectric Actuator Technologies

Emerging trends in piezoelectric actuator technologies highlight the integration of nanomaterials to enhance sensitivity and response time, enabling precise control in microelectromechanical systems (MEMS). Advanced fabrication techniques such as 3D printing support the development of customizable actuator architectures for applications in medical devices and robotics. Innovations in energy harvesting combine piezoelectric actuators with smart systems, boosting efficiency in wearable electronics and IoT devices.

example of piezoelectric in actuator Infographic

samplerz.com

samplerz.com