Machine vision in robotics enables automated inspection and quality control in manufacturing environments. High-resolution cameras capture detailed images of products on assembly lines, while advanced algorithms analyze these images to detect defects or inconsistencies. This technology increases accuracy and reduces human error, leading to improved production efficiency and lower costs. Robotic systems equipped with machine vision can also perform precise parts assembly by identifying and positioning components correctly. Sensors combined with image recognition software guide robotic arms in complex tasks such as sorting, packaging, and material handling. Industries like automotive and electronics widely adopt machine vision to optimize operations and enhance product quality.

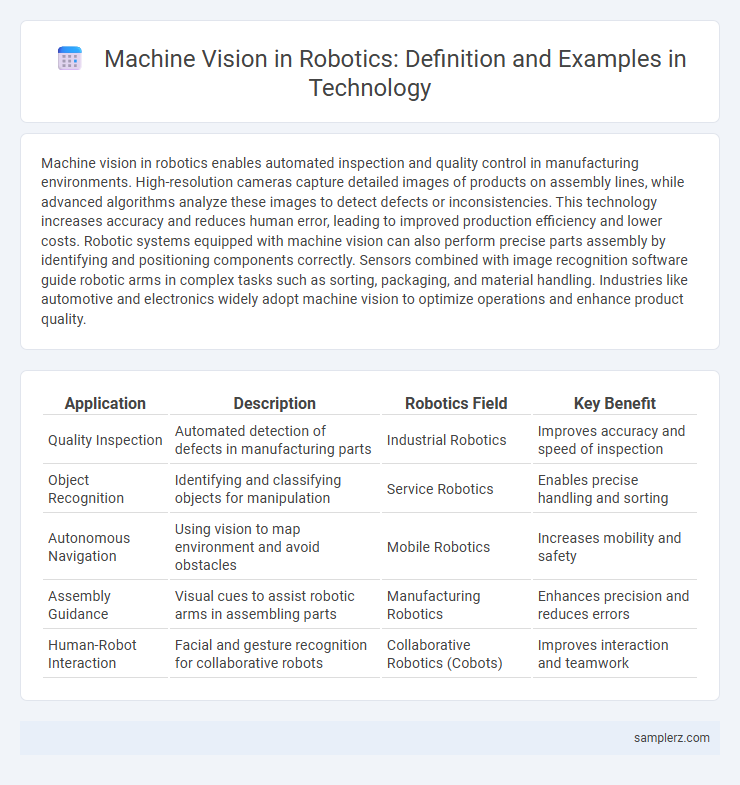

Table of Comparison

| Application | Description | Robotics Field | Key Benefit |

|---|---|---|---|

| Quality Inspection | Automated detection of defects in manufacturing parts | Industrial Robotics | Improves accuracy and speed of inspection |

| Object Recognition | Identifying and classifying objects for manipulation | Service Robotics | Enables precise handling and sorting |

| Autonomous Navigation | Using vision to map environment and avoid obstacles | Mobile Robotics | Increases mobility and safety |

| Assembly Guidance | Visual cues to assist robotic arms in assembling parts | Manufacturing Robotics | Enhances precision and reduces errors |

| Human-Robot Interaction | Facial and gesture recognition for collaborative robots | Collaborative Robotics (Cobots) | Improves interaction and teamwork |

Introduction to Machine Vision in Robotics

Machine vision in robotics involves the use of cameras and image processing algorithms to enable robots to perceive and interpret their environment with high precision. Advanced machine vision systems facilitate tasks such as object recognition, quality inspection, and autonomous navigation in manufacturing and logistics. Integrating deep learning models with real-time image analysis enhances the accuracy and adaptability of robotic applications across various industrial sectors.

Industrial Automation: Quality Inspection Systems

Machine vision in industrial automation plays a crucial role in quality inspection systems by enabling real-time defect detection and measurement accuracy on production lines. High-resolution cameras combined with advanced image processing algorithms identify micro-level imperfections, ensuring consistency and compliance with manufacturing standards. Integration of machine vision with robotic arms facilitates automated sorting and rejection of defective products, significantly improving efficiency and reducing human error.

Object Recognition in Autonomous Robots

Object recognition in autonomous robots leverages advanced machine vision techniques such as convolutional neural networks (CNNs) to accurately identify and classify objects in real-time environments. High-resolution cameras paired with depth sensors enable robots to perceive spatial information, facilitating precise manipulation and navigation. This capability enhances automation in industries like manufacturing, logistics, and agriculture by improving task efficiency and collision avoidance.

Vision-Guided Robotic Arms in Manufacturing

Vision-guided robotic arms in manufacturing utilize advanced machine vision systems to enhance precision and efficiency in assembly lines. These systems employ high-resolution cameras and AI algorithms to detect objects, identify defects, and guide robotic arms for accurate manipulation and placement. This integration reduces human error, speeds up production cycles, and ensures consistent product quality.

Navigation and Obstacle Avoidance with Machine Vision

Machine vision in robotics enables precise navigation by using cameras and sensors to create real-time 3D maps of the environment. Advanced algorithms process visual data to detect obstacles and calculate optimal paths, ensuring smooth and safe movement. Autonomous robots equipped with machine vision systems improve operational efficiency in complex terrains like warehouses and manufacturing floors.

Sorting and Packaging Robots Using Visual Systems

Sorting and packaging robots utilize advanced machine vision systems to identify, categorize, and handle various products with high precision and speed. These robotic systems employ cameras and image processing algorithms to detect product features, barcodes, and defects, enabling automated sorting on conveyor belts and precise packaging alignment. Integration of deep learning models enhances the accuracy of object recognition and adapts to diverse packaging requirements in real-time industrial environments.

Automated Agricultural Robots with Vision Capabilities

Automated agricultural robots equipped with advanced machine vision systems enable precise crop monitoring, pest detection, and targeted spraying, significantly enhancing yield and reducing chemical usage. These robots utilize high-resolution cameras and AI algorithms to differentiate between crops and weeds, allowing for accurate intervention without damaging plants. Machine vision integration in robotics streamlines farming operations, increases efficiency, and supports sustainable agriculture practices.

Machine Vision in Collaborative (Cobot) Robotics

Machine vision in collaborative robotics enables precise object recognition and spatial awareness, enhancing human-robot interaction and safety in shared workspaces. Advanced image processing algorithms allow cobots to identify parts, monitor assembly quality, and adapt to dynamic environments in real time. This integration boosts productivity and reduces errors in manufacturing processes where robots and humans work side by side.

Defect Detection in Electronics Assembly via Vision Systems

Machine vision in robotics enables precise defect detection in electronics assembly by utilizing high-resolution cameras and advanced image processing algorithms to identify soldering errors, component misalignment, and surface defects. Vision systems enhance production quality by providing real-time inspection and automated sorting, significantly reducing human error and increasing throughput. Integration of deep learning models further improves defect classification accuracy and adapts to variations in complex electronic assemblies.

Future Trends of Machine Vision in Robotics

Machine vision in robotics is evolving with advancements in AI-powered image recognition and 3D vision systems, enabling robots to perform complex tasks with greater accuracy. Future trends include integration of deep learning algorithms for real-time decision-making, enhanced object detection in dynamic environments, and collaborative robots operating safely alongside humans. These innovations are expected to revolutionize industries such as manufacturing, logistics, and healthcare by improving automation efficiency and precision.

example of machine vision in robotics Infographic

samplerz.com

samplerz.com