Laminar flow in cooling technology refers to the smooth, orderly movement of coolant fluids over surfaces, minimizing turbulence and enhancing heat transfer efficiency. This controlled flow pattern is critical in electronic cooling systems, such as in microchannel heat sinks used in high-performance CPUs and GPUs. Data shows that laminar flow reduces pressure drops and ensures uniform temperature distribution, improving the overall thermal management of electronic devices. In industrial applications, laminar flow cooling is utilized in precision laser cutting and semiconductor manufacturing, where stable thermal conditions are essential. Research indicates a significant improvement in equipment lifespan and performance when laminar flow cooling is implemented. The efficiency of heat exchangers and liquid cooling loops is greatly increased by maintaining laminar flow, achieving enhanced system reliability and energy savings.

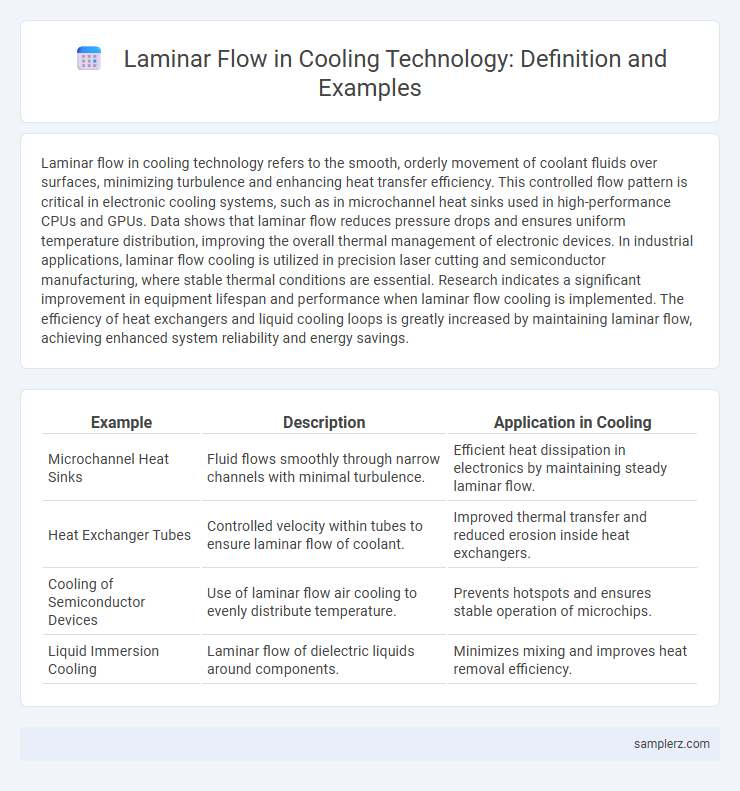

Table of Comparison

| Example | Description | Application in Cooling |

|---|---|---|

| Microchannel Heat Sinks | Fluid flows smoothly through narrow channels with minimal turbulence. | Efficient heat dissipation in electronics by maintaining steady laminar flow. |

| Heat Exchanger Tubes | Controlled velocity within tubes to ensure laminar flow of coolant. | Improved thermal transfer and reduced erosion inside heat exchangers. |

| Cooling of Semiconductor Devices | Use of laminar flow air cooling to evenly distribute temperature. | Prevents hotspots and ensures stable operation of microchips. |

| Liquid Immersion Cooling | Laminar flow of dielectric liquids around components. | Minimizes mixing and improves heat removal efficiency. |

Introduction to Laminar Flow in Cooling Technology

Laminar flow in cooling technology involves the smooth, orderly movement of fluid over surfaces, minimizing turbulence and enhancing heat transfer efficiency in devices like computer processors and electronic components. This controlled flow reduces thermal resistance and prevents hotspots, ensuring optimal temperature regulation in high-performance systems. Applications include liquid cooling loops and heat exchangers where laminar flow maintains consistent, efficient cooling for sensitive equipment.

Key Principles of Laminar Flow in Thermal Management

Laminar flow in thermal management is characterized by smooth, orderly fluid motion with low Reynolds numbers, ensuring efficient heat transfer through steady conductive and convective processes. Key principles include minimizing turbulence to reduce thermal resistance and maintaining a stable velocity profile to enhance uniform cooling across heat exchanger surfaces. This controlled flow regime optimizes cooling performance in applications such as liquid-cooled electronics and aerospace thermal systems.

Laminar Flow Applications in Electronic Device Cooling

Laminar flow is crucial in electronic device cooling, as it ensures a smooth, steady coolant path that minimizes turbulence and enhances heat transfer efficiency. Applications include cooling in microchannels within CPUs and GPUs, where controlled laminar flow improves thermal management and extends device lifespan. Optimizing laminar flow in heat sinks and liquid cooling systems reduces hotspots and maintains consistent temperature regulation in high-performance electronics.

Laminar Flow Techniques in Data Center Cooling

Laminar flow techniques in data center cooling involve directing smooth, non-turbulent airflow over server components to enhance heat dissipation and prevent hotspots. By using laminar flow hoods and precision airflow containment systems, data centers optimize cooling efficiency while reducing energy consumption. These methods improve temperature control, extend equipment lifespan, and support high-density server configurations.

Utilizing Laminar Flow in HVAC Systems for Efficient Cooling

Utilizing laminar flow in HVAC systems enhances cooling efficiency by minimizing turbulence and ensuring uniform airflow distribution across cooling coils. This steady, smooth flow reduces energy consumption and improves heat transfer rates, leading to optimized system performance. Laminar flow also prevents hot spots and maintains consistent indoor air quality in commercial and residential environments.

Laminar Flow in Industrial Equipment Cooling Solutions

Laminar flow in industrial equipment cooling solutions ensures a smooth, uninterrupted coolant movement, reducing turbulence and enhancing heat transfer efficiency. This controlled flow minimizes energy consumption and prolongs the lifespan of sensitive machinery by preventing hotspots and thermal stress. Industries such as semiconductor manufacturing and precision optics heavily rely on laminar cooling systems for maintaining optimal operating temperatures and product quality.

Advanced Laminar Flow Heat Exchangers

Advanced laminar flow heat exchangers enhance cooling efficiency by maintaining smooth, non-turbulent fluid flow, reducing thermal resistance and pressure drops. These exchangers utilize streamlined microchannel designs and precision surface finishes to sustain laminar flow conditions, optimizing heat transfer rates while minimizing energy consumption. Integration of such technology in electronics cooling systems significantly improves thermal management and reliability of high-performance devices.

Laminar Flow for Cooling Microprocessors and Microchips

Laminar flow plays a critical role in cooling microprocessors and microchips by providing a controlled, uniform airflow that minimizes thermal resistance and enhances heat dissipation. This steady, unidirectional flow reduces turbulence-related hotspots, ensuring consistent temperature regulation essential for maintaining optimal performance and extending device lifespan. Advanced cooling systems utilize laminar flow designs to improve efficiency in high-density electronic components by facilitating precise thermal management.

Comparison: Laminar vs. Turbulent Flow in Cooling Systems

Laminar flow in cooling systems provides a smooth and orderly fluid movement, reducing friction and heat transfer resistance compared to turbulent flow, which is characterized by chaotic and irregular fluid motion. This orderly flow enhances precise temperature control in sensitive electronics but may result in lower overall heat transfer rates than turbulent flow, which increases mixing and convective heat transfer efficiency. Designers commonly select laminar flow for applications requiring minimal vibration and noise, while turbulent flow is preferred for higher cooling capacity due to its superior thermal performance.

Future Trends of Laminar Flow in Cooling Technology

Future trends in laminar flow cooling technology emphasize the integration of advanced microfluidic channels and nanostructured surfaces to enhance heat dissipation efficiency in high-performance electronics. The development of smart cooling systems utilizing real-time sensors and AI algorithms aims to dynamically control laminar flow patterns, optimizing thermal management in data centers and electric vehicles. Emerging materials such as graphene and phase change composites are set to revolutionize laminar flow applications by enabling ultra-thin, highly conductive cooling layers with minimal energy consumption.

example of laminar flow in cooling Infographic

samplerz.com

samplerz.com