Planogram validation in a liquor store involves ensuring that product placement aligns precisely with the predefined layout designed to optimize sales and customer experience. Retail staff or automated systems scan shelves to verify the presence, position, and facing of each liquor bottle according to the planogram specifications. Data collected during this process helps identify out-of-stock items, misplaced products, and compliance with promotional displays, supporting inventory accuracy and maximizing shelf efficiency. Using specialized software tools, planogram validation captures detailed information about SKU arrangement and shelf space utilization in the liquor store. This data is analyzed to generate reports highlighting discrepancies and areas for improvement in product placement strategies. Implementing regular planogram validations enables store managers to maintain consistent presentation standards, boost product visibility, and drive increased revenue in a competitive retail environment.

Table of Comparison

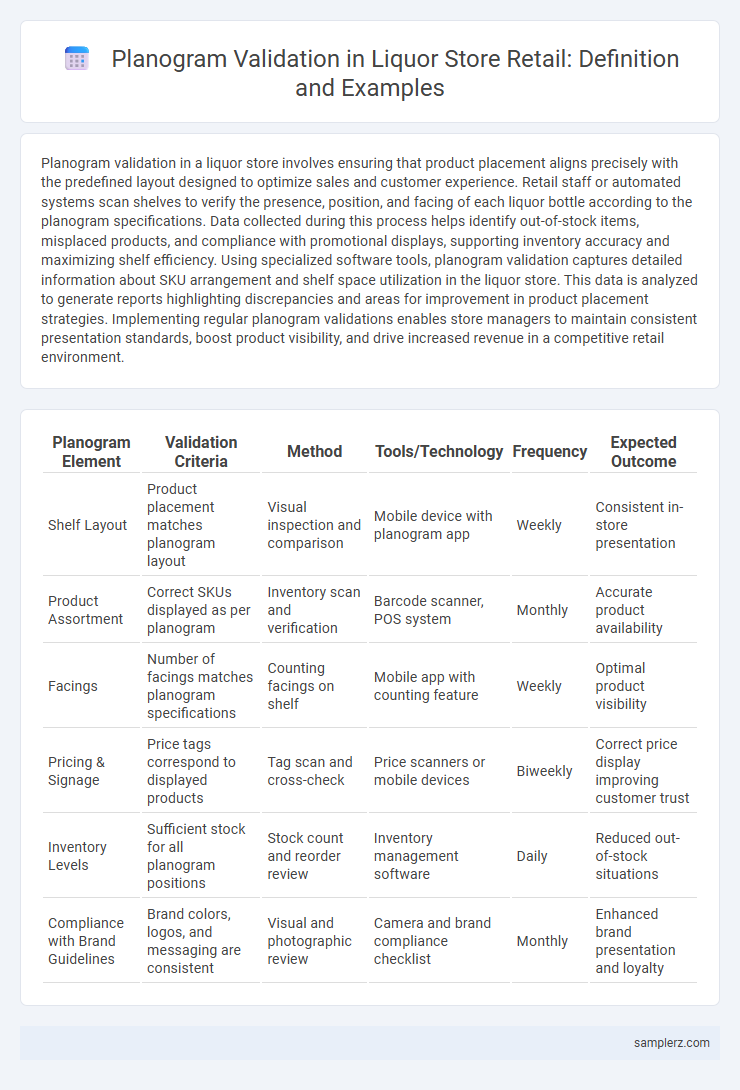

| Planogram Element | Validation Criteria | Method | Tools/Technology | Frequency | Expected Outcome |

|---|---|---|---|---|---|

| Shelf Layout | Product placement matches planogram layout | Visual inspection and comparison | Mobile device with planogram app | Weekly | Consistent in-store presentation |

| Product Assortment | Correct SKUs displayed as per planogram | Inventory scan and verification | Barcode scanner, POS system | Monthly | Accurate product availability |

| Facings | Number of facings matches planogram specifications | Counting facings on shelf | Mobile app with counting feature | Weekly | Optimal product visibility |

| Pricing & Signage | Price tags correspond to displayed products | Tag scan and cross-check | Price scanners or mobile devices | Biweekly | Correct price display improving customer trust |

| Inventory Levels | Sufficient stock for all planogram positions | Stock count and reorder review | Inventory management software | Daily | Reduced out-of-stock situations |

| Compliance with Brand Guidelines | Brand colors, logos, and messaging are consistent | Visual and photographic review | Camera and brand compliance checklist | Monthly | Enhanced brand presentation and loyalty |

Importance of Planogram Compliance in Liquor Stores

Planogram validation in liquor stores ensures optimal product placement, maximizes shelf space utilization, and enhances customer shopping experience by maintaining brand visibility and consistency. Compliance with planograms reduces inventory discrepancies, prevents stockouts of popular liquor brands, and drives higher sales through strategic product arrangement. Retailers achieve increased profitability and operational efficiency by adhering to planogram standards tailored to liquor category dynamics and consumer buying patterns.

Common Challenges in Liquor Store Planogram Validation

Planogram validation in liquor stores often faces challenges such as inconsistent shelf labeling, frequent product substitutions, and variations in bottle sizes which disrupt space allocation. Ensuring compliance with brand-specific display requirements and managing rotation of seasonal or promotional items further complicate accurate shelf arrangement. Data collection errors during audits and limited real-time visibility also hinder effective planogram adherence and inventory management.

Step-by-Step Planogram Validation Process for Spirits

A step-by-step planogram validation process for spirits in a liquor store begins with comparing the shelf layout against the approved planogram to ensure correct product placement and facing counts. Use handheld scanning devices or planogram software to verify SKU accuracy, brand grouping, and compliance with promotional displays. Finalize by documenting discrepancies and adjusting shelf arrangements to optimize product visibility, inventory management, and sales performance.

Tools and Technologies for Planogram Validation

Planogram validation in liquor stores leverages advanced tools such as handheld barcode scanners, shelf cameras, and digital planogram software to ensure accurate product placement and inventory management. Technologies like RFID tagging and mobile applications enable real-time data capture and automated compliance checks, increasing operational efficiency. Image recognition software integrated with AI provides precise shelf auditing, detecting out-of-stock items and planogram deviations quickly and accurately.

Real-World Example: Auditing a Whiskey Aisle Planogram

A liquor store conducted a planogram validation by auditing the whiskey aisle to ensure shelf placement matched the predefined layout designed to optimize product visibility and sales. The audit revealed discrepancies such as misplaced premium brands and inconsistent spacing between bottles, prompting immediate adjustments to enhance customer navigation and maximize sales potential. Real-time data collection through barcode scanning and shelf imaging facilitated accurate verification of planogram compliance and inventory levels.

Impact of Planogram Validation on Sales and Shrinkage

Planogram validation in liquor stores ensures optimal product placement aligned with consumer behavior, directly boosting sales by increasing product visibility and accessibility. Accurate planogram compliance reduces shrinkage by minimizing misplaced or overstocked items, enabling better inventory control and loss prevention. Retailers experience improved turnover rates and enhanced profitability through precise shelf arrangement verified by regular validation processes.

Case Study: Wine Section Planogram Compliance Check

The wine section planogram compliance check in a liquor store involved auditing shelf placements against the predetermined layout to maximize sales and enhance customer experience. Data analysis revealed that 95% of premium wine brands were displayed according to planogram specifications, ensuring optimal visibility and accessibility. Non-compliant areas, primarily in new product introductions, were promptly adjusted, resulting in a 12% increase in wine category sales within one month.

Key Metrics for Evaluating Liquor Store Planogram Accuracy

Planogram validation in liquor stores focuses on key metrics such as product facings accuracy, shelf compliance rate, and out-of-stock occurrences to ensure optimal inventory display and maximized sales potential. Measuring shelf space allocation against the planogram helps identify discrepancies in product placement and category adjacency, directly impacting customer shopping experience and purchase decisions. Regular audits using these metrics enable retailers to maintain visual merchandising standards and drive increased revenue through improved shelf organization and product accessibility.

Tips for Staff Training on Planogram Validation

Effective staff training on planogram validation in liquor stores includes hands-on practice with shelving layouts and product placement accuracy to ensure compliance with brand standards. Implementing regular refresher sessions and using digital tools for real-time validation helps employees quickly identify and correct deviations. Emphasizing the importance of SKU-level accuracy and maintaining facing counts improves inventory management and enhances customer experience.

Leveraging Planogram Data for Optimized Product Placement

Leveraging planogram data in liquor stores enables precise product placement by analyzing customer purchase patterns and shelf performance metrics. Utilizing planogram validation tools ensures compliance with layout standards, enhances visibility of high-margin items, and maximizes shelf space efficiency. Continuous validation helps retailers adapt to seasonal trends and regional preferences, driving increased sales and improved inventory turnover.

example of planogram validation in liquor store Infographic

samplerz.com

samplerz.com