Cross-docking in retail distribution involves directly transferring products from inbound to outbound transportation with minimal or no storage time. For example, a large retail chain may receive shipments of electronics from multiple suppliers at a central distribution center. The products are sorted and immediately loaded onto trucks destined for individual retail stores, reducing inventory holding costs and speeding up delivery. Another example includes perishable goods like fresh produce arriving at a distribution hub from various farms. The items are quickly inspected and dispatched to grocery stores without being stored in a warehouse. This method enhances product freshness and optimizes supply chain efficiency by minimizing handling and storage times.

Table of Comparison

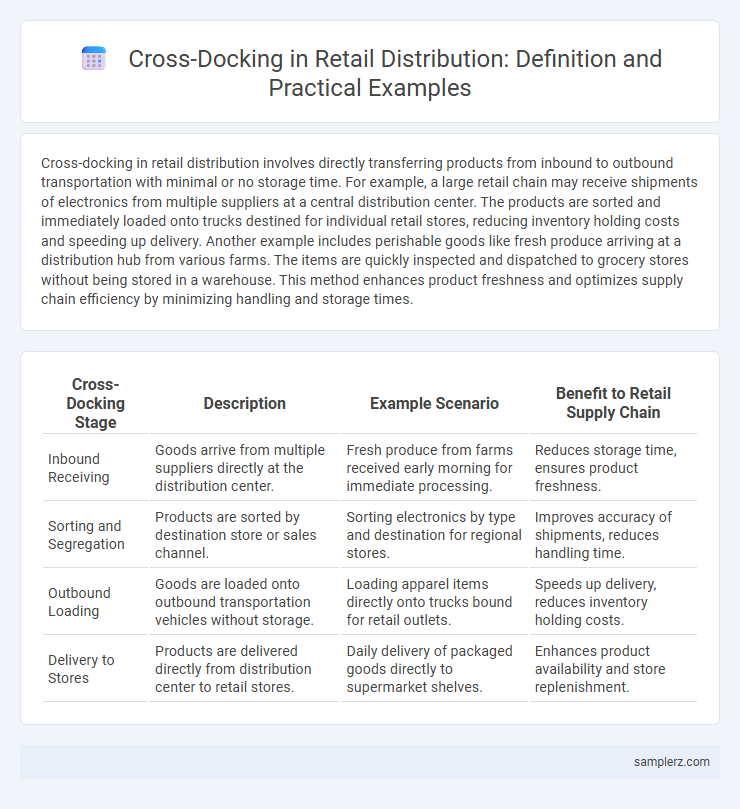

| Cross-Docking Stage | Description | Example Scenario | Benefit to Retail Supply Chain |

|---|---|---|---|

| Inbound Receiving | Goods arrive from multiple suppliers directly at the distribution center. | Fresh produce from farms received early morning for immediate processing. | Reduces storage time, ensures product freshness. |

| Sorting and Segregation | Products are sorted by destination store or sales channel. | Sorting electronics by type and destination for regional stores. | Improves accuracy of shipments, reduces handling time. |

| Outbound Loading | Goods are loaded onto outbound transportation vehicles without storage. | Loading apparel items directly onto trucks bound for retail outlets. | Speeds up delivery, reduces inventory holding costs. |

| Delivery to Stores | Products are delivered directly from distribution center to retail stores. | Daily delivery of packaged goods directly to supermarket shelves. | Enhances product availability and store replenishment. |

Introduction to Cross-Docking in Retail Distribution

Cross-docking in retail distribution streamlines inventory flow by transferring products directly from inbound to outbound transportation with minimal storage time. This method reduces warehouse costs and accelerates delivery, enhancing overall supply chain efficiency. Major retailers like Walmart utilize cross-docking to handle high-volume shipments, ensuring timely product availability and lower operational expenses.

Key Benefits of Cross-Docking for Retailers

Cross-docking in retail distribution minimizes inventory holding by directly transferring products from inbound to outbound transportation, accelerating delivery times and reducing storage costs. This streamlined process enhances supply chain efficiency, enabling retailers to respond swiftly to market demand and improve customer satisfaction. Lower handling and transportation expenses contribute to increased profit margins while maintaining product freshness and availability.

Leading Retailers Successfully Using Cross-Docking

Walmart exemplifies cross-docking by streamlining its supply chain, reducing storage time, and swiftly moving products from suppliers to stores. Target employs cross-docking to enhance inventory turnover and minimize warehousing costs, ensuring faster replenishment on retail shelves. Costco's efficient cross-docking system supports bulk deliveries directly to distribution centers, optimizing logistics and maintaining competitive pricing for consumers.

Real-World Example: Walmart’s Cross-Docking Strategy

Walmart's cross-docking strategy revolutionizes retail distribution by minimizing inventory holding through direct transfer of products from suppliers to stores, significantly reducing handling costs and delivery times. By coordinating real-time data and supplier shipments, Walmart efficiently replenishes stock, ensuring high product availability and lower operational expenses. This streamlined approach supports Walmart's competitive pricing and supply chain agility, setting a benchmark in retail logistics.

Case Study: Amazon’s Cross-Docking Operations

Amazon's cross-docking operations streamline distribution by receiving products from suppliers and immediately transferring them to outbound trucks, reducing storage time and costs. Its fulfillment centers use advanced robotics and real-time inventory tracking to optimize the flow of goods, enhancing delivery speed and efficiency. This model supports Amazon's ability to offer same-day or next-day delivery while minimizing warehouse inventory holding.

Cross-Docking at Work: Grocery Chains and Fresh Food

Cross-docking in grocery chains accelerates the distribution of fresh food by transferring products directly from inbound to outbound trucks, minimizing storage time and preserving freshness. This logistic strategy streamlines inventory flow, reduces warehousing costs, and ensures timely delivery of perishable items to retail shelves. Grocery retailers implementing cross-docking achieve enhanced supply chain efficiency and improved customer satisfaction through faster replenishment cycles.

Fashion Retail Success: Zara’s Cross-Docking Model

Zara's cross-docking model streamlines inventory by quickly transferring fashion items from suppliers to stores without long-term storage, reducing lead times and inventory costs. This efficient distribution system supports rapid response to trends, enabling Zara to refresh collections twice a week and maintain high sales velocity. The seamless coordination between suppliers, distribution centers, and retail outlets exemplifies cross-docking's role in achieving agility and competitiveness in fashion retail.

Technology’s Role in Streamlining Cross-Docking

Technology plays a pivotal role in streamlining cross-docking within retail distribution by enabling real-time inventory tracking through advanced warehouse management systems (WMS) and automated sorting technologies. Electronic Data Interchange (EDI) facilitates seamless communication between suppliers and retailers, reducing delays and errors in shipment processing. Integration of RFID and IoT devices ensures accurate and efficient handling of goods, enhancing the speed and accuracy of cross-docking operations.

Overcoming Challenges in Cross-Docking Implementation

Efficient cross-docking in retail distribution relies on precise real-time inventory tracking and seamless coordination between suppliers and distribution centers to overcome challenges such as misaligned delivery schedules and product damage risks. Investing in advanced warehouse management systems (WMS) and collaborative communication platforms helps retailers minimize handling time and optimize load sequencing, ensuring faster throughput. Data-driven forecasting and staff training are critical to mitigating errors during product sorting and maintaining consistent service levels amid fluctuating demand.

Future Trends in Retail Cross-Docking Distribution

Future trends in retail cross-docking distribution emphasize automation through robotics and AI-driven sorting systems, significantly reducing handling time and increasing accuracy. Integration of Internet of Things (IoT) devices enables real-time inventory tracking and improved supply chain visibility, enhancing responsiveness to demand fluctuations. Sustainable practices, such as eco-friendly packaging and optimized transportation routes, are becoming integral to cross-docking strategies to reduce carbon footprints and operational costs.

example of cross-docking in distribution Infographic

samplerz.com

samplerz.com