Planogram auditing in an office supply store involves systematically reviewing product placements against a predefined visual merchandising plan. Auditors collect data on shelf layouts, product facings, and inventory levels to ensure compliance with the planogram standards. This process helps optimize shelf space, improve product visibility, and enhance overall shopper experience. Key entities in planogram auditing include product categories like notebooks, pens, and printer cartridges, as well as shelf zones and promotional displays. Data collected typically includes SKU counts, stockout instances, and adherence to brand positioning guidelines. Accurate auditing supports inventory management, drives sales performance, and helps maintain store consistency across multiple locations.

Table of Comparison

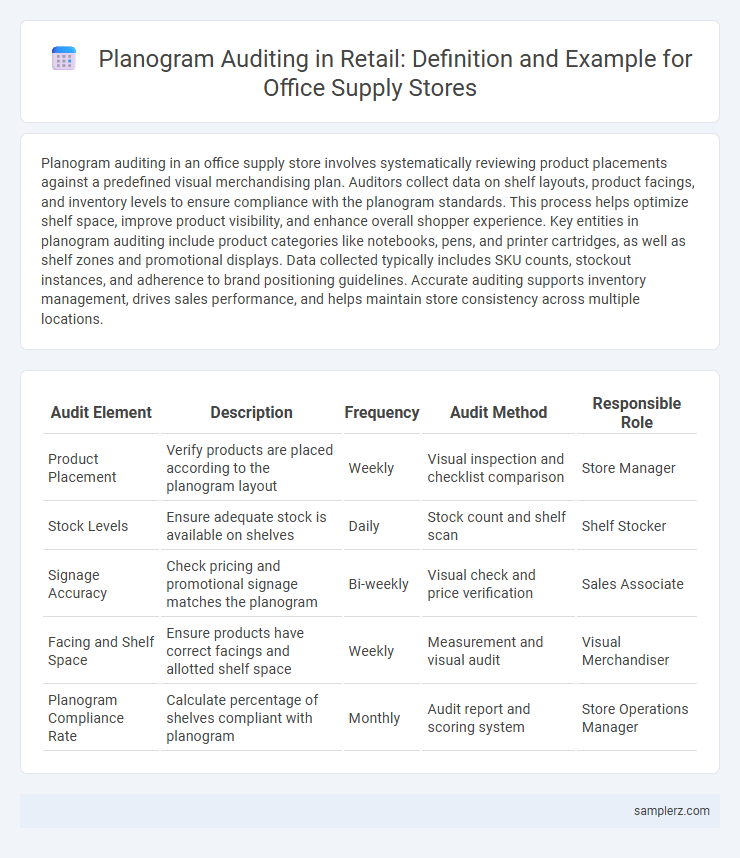

| Audit Element | Description | Frequency | Audit Method | Responsible Role |

|---|---|---|---|---|

| Product Placement | Verify products are placed according to the planogram layout | Weekly | Visual inspection and checklist comparison | Store Manager |

| Stock Levels | Ensure adequate stock is available on shelves | Daily | Stock count and shelf scan | Shelf Stocker |

| Signage Accuracy | Check pricing and promotional signage matches the planogram | Bi-weekly | Visual check and price verification | Sales Associate |

| Facing and Shelf Space | Ensure products have correct facings and allotted shelf space | Weekly | Measurement and visual audit | Visual Merchandiser |

| Planogram Compliance Rate | Calculate percentage of shelves compliant with planogram | Monthly | Audit report and scoring system | Store Operations Manager |

Introduction to Planogram Auditing in Office Supply Stores

Planogram auditing in office supply stores ensures accurate product placement and optimal shelf organization by verifying compliance with the predefined layout. This process involves detailed inspection of inventory arrangement, shelf labels, and product facings to maximize product visibility and sales potential. Regular planogram audits reduce stockouts and improve customer shopping experience by maintaining consistent store presentation across all locations.

Importance of Planogram Compliance for Office Retailers

Planogram auditing in office supply stores ensures shelves are organized according to strategic layouts, maximizing product visibility and sales efficiency. Consistent planogram compliance drives inventory accuracy, enhances customer experience, and reduces stockouts or overstock situations. Retailers achieve improved operational performance and higher profit margins by adhering strictly to prescribed planogram arrangements.

Common Planogram Audit Procedures in Office Supply Stores

Planogram auditing in office supply stores typically involves verifying product placement accuracy against the established layout, checking shelf labels for correct pricing and product information, and ensuring inventory levels match planogram requirements. Auditors systematically document discrepancies such as misplaced items, out-of-stock products, and shelf space violations using mobile scanning devices or audit software. Regular planogram audits help maintain visual merchandising standards, improve product visibility, and enhance customer shopping experience while boosting sales efficiency.

Example Checklist for Office Supply Planogram Auditing

A comprehensive example checklist for office supply planogram auditing includes verifying product placement accuracy, ensuring compliance with shelf labels and price tags, and checking for proper stock levels and shelf organization. Auditors also inspect product facings to maintain visual appeal and confirm adherence to planogram layouts specific to office essentials like pens, notebooks, and printer cartridges. Consistent use of the checklist improves inventory management, reduces stockouts, and enhances customer shopping experience in retail office supply stores.

Visual Merchandising Standards for Stationery Sections

Planogram auditing in office supply stores ensures the stationery sections adhere to visual merchandising standards by verifying product placement, shelf labeling, and inventory levels align with the approved layout. Auditors assess compliance with color blocking, face-out display techniques, and category adjacency to enhance product visibility and shopper navigation. Accurate planogram execution drives sales optimization, inventory management, and consistent brand presentation within the stationery category.

Assessing Planogram Execution: Printer and Ink Aisle Audit

The printer and ink aisle audit evaluates shelf placement accuracy, product facings, and compliance with the planogram to maximize sales potential and inventory visibility. Auditors measure shelf alignment against the planogram's specifications, ensuring that best-selling printer models and popular ink cartridges are prominently displayed and properly labeled. This detailed assessment identifies discrepancies such as misplaced SKUs or insufficient stock facings, enabling timely corrective actions to optimize merchandising effectiveness.

Real-Life Case: Planogram Audit for Writing Instruments

A planogram audit in an office supply store for writing instruments involved assessing product placement accuracy, shelf compliance, and inventory levels against the approved layout. The audit revealed discrepancies such as misaligned pen brands and understocked markers, prompting restocking and rearrangement to enhance visibility and sales. Implementation of a digital planogram tool enabled real-time monitoring, improving adherence and boosting writing instruments category performance by 15%.

Identifying Stock Issues through Planogram Audits

Planogram audits in office supply stores reveal stock issues such as misplaced items, out-of-stock products, and inconsistent shelving that disrupt inventory accuracy and customer experience. Auditors use sales data and shelf compliance reports to pinpoint discrepancies between actual stock and planogram layouts, ensuring optimal product placement. Effective identification of stock issues through these audits drives restocking efficiency and reduces lost sales.

Using Technology for Efficient Planogram Auditing

Planogram auditing in office supply stores leverages advanced technologies such as handheld scanners and mobile apps to streamline shelf compliance checks and inventory management. These tools enable real-time data capture, improving accuracy and reducing audit times by automatically comparing shelf layouts against digital planogram standards. Integration with cloud-based platforms facilitates centralized reporting and analytics, empowering store managers to quickly identify discrepancies and optimize product placement for enhanced customer experience and sales.

Best Practices for Planogram Audits in Office Retail Environments

Planogram auditing in office supply stores involves systematically verifying product placement and inventory accuracy to enhance customer experience and maximize sales. Best practices include using digital tools for real-time shelf data capture, cross-referencing SKU compliance with planogram standards, and scheduling regular audits to identify discrepancies promptly. Fostering collaboration between merchandising teams and store associates ensures consistent adherence to planogram layouts and drives improved store performance.

example of planogram auditing in office supply store Infographic

samplerz.com

samplerz.com