Planogram compliance in convenience stores ensures that product placement aligns with the retailer's strategic layout designed to maximize sales and enhance customer experience. For example, a convenience store planogram may mandate that popular snack brands like Doritos and Lay's be positioned at eye level on end caps to attract impulse buyers. Data from sales analytics platforms can confirm whether adherence to the planogram correlates with increased sales volume and inventory turnover rates. Store managers use planogram compliance software to verify that shelves are stocked according to the predefined layout, focusing on product facings, shelf heights, and promotional displays. In a typical scenario, a morning compliance check might reveal that energy drinks such as Red Bull and Monster are correctly placed near the checkout counter, a prime spot for last-minute purchases. Reports generated from these checks provide actionable insights for retailers and suppliers, optimizing inventory management and improving overall merchandising efficiency.

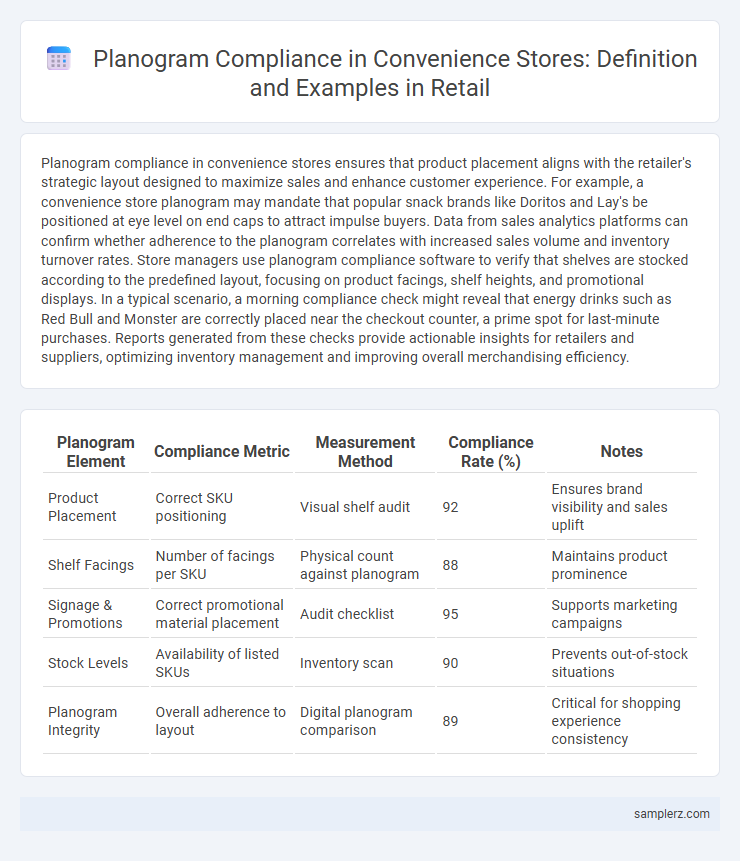

Table of Comparison

| Planogram Element | Compliance Metric | Measurement Method | Compliance Rate (%) | Notes |

|---|---|---|---|---|

| Product Placement | Correct SKU positioning | Visual shelf audit | 92 | Ensures brand visibility and sales uplift |

| Shelf Facings | Number of facings per SKU | Physical count against planogram | 88 | Maintains product prominence |

| Signage & Promotions | Correct promotional material placement | Audit checklist | 95 | Supports marketing campaigns |

| Stock Levels | Availability of listed SKUs | Inventory scan | 90 | Prevents out-of-stock situations |

| Planogram Integrity | Overall adherence to layout | Digital planogram comparison | 89 | Critical for shopping experience consistency |

Importance of Planogram Compliance in Convenience Stores

Planogram compliance in convenience stores ensures optimal product placement, maximizing shelf space efficiency and boosting sales by guiding customers directly to high-demand items. Maintaining consistent planogram adherence reduces inventory discrepancies and improves stock replenishment accuracy, leading to enhanced customer satisfaction through product availability. Effective planogram execution supports brand standards and promotional strategies, driving overall profitability and competitive advantage in the retail sector.

Key Elements of an Effective Planogram

Effective planogram compliance in convenience stores hinges on precise product placement, ensuring high-demand items are positioned at eye level to maximize visibility and sales. Consistent shelf labeling and accurate inventory counts facilitate quick restocking and minimize out-of-stock scenarios. Strategic use of signage and color coding guides customer navigation, enhancing shopping experience and driving impulse purchases.

Real-World Examples of Planogram Compliance

A convenience store in Chicago increased sales by 18% after implementing strict planogram compliance for snack aisles, ensuring product placement aligned with manufacturer recommendations. Another example includes a New York convenience chain that reduced out-of-stock instances by 25% through routine audits and employee training on planogram standards. These real-world cases demonstrate how adherence to planogram compliance directly impacts inventory management and sales performance in retail environments.

Step-by-Step Planogram Compliance Process

Step-by-step planogram compliance in convenience stores begins with a detailed analysis of the planogram layout to ensure accurate product placement according to category, brand, and shelf space allocation. Store associates then conduct regular audits using mobile scanning devices or compliance software to verify shelf tags, facings, and inventory levels match the prescribed planogram. Final adjustments are made based on audit results, with documentation and feedback loops established for continuous improvement and maintaining optimal merchandising standards.

Visual Merchandising Strategies for Convenience Stores

Planogram compliance in convenience stores enhances product visibility by ensuring strategic placement of high-demand items at eye level and utilizing shelf space efficiently to maximize sales. Visual merchandising strategies include grouping complementary products, employing color-coded signage, and maintaining consistent brand presentation to attract customer attention. Regular audits and staff training help uphold these standards, driving improved customer experience and higher transaction values.

Common Challenges in Planogram Implementation

Planogram compliance in convenience stores often faces challenges such as limited shelf space, frequent product assortment changes, and inconsistent staff training. These issues lead to misplacement of products, stockouts, and reduced customer satisfaction, impacting overall sales performance. Effective use of digital planogram tools and regular audits can mitigate these common obstacles, ensuring better product visibility and inventory management.

Tools and Technologies for Ensuring Planogram Compliance

Planogram compliance in convenience stores is ensured through advanced tools such as shelf-scanning cameras and RFID technology, which provide real-time inventory tracking and product placement verification. Mobile audit applications equipped with AI-driven image recognition enable store associates to quickly identify discrepancies between actual shelf layout and the approved planogram. Cloud-based planogram management platforms centralize data, allowing for automated alerts and detailed reporting to maintain consistent merchandising standards across multiple store locations.

Measuring the Impact of Planogram Compliance on Sales

Planogram compliance in convenience stores can be measured by tracking sales data before and after implementing the prescribed product placement, revealing a direct correlation between adherence and increased revenue. Studies show that stores with over 90% planogram compliance experience up to a 15% boost in sales of promoted items due to optimized product visibility and customer convenience. Utilizing sales analytics and shelf auditing tools helps retailers quantify the effectiveness of planograms, driving better inventory management and maximizing profit margins.

Staff Training for Planogram Adherence

Effective staff training for planogram adherence in convenience stores significantly enhances product placement consistency, ensuring that shelves reflect the intended layout for optimal customer experience. Training programs emphasize precise shelf stocking, correct product facings, and timely restocking to maintain compliance with the visual merchandising strategy. Regular assessments and hands-on workshops empower retail employees to identify and correct planogram deviations, directly impacting sales performance and inventory management.

Checklist for Maintaining Planogram Compliance

Regularly verify product placement against the planogram to ensure correct facing, spacing, and shelf alignment in the convenience store. Use a detailed checklist including SKU accuracy, promotional display presence, and stock level maintenance to guarantee consistency. Auditing shelf tags, verifying pricing accuracy, and confirming inventory rotation support planogram compliance and enhance shopper experience.

example of planogram compliance in convenience store Infographic

samplerz.com

samplerz.com