Cross-docking in a retail distribution center involves receiving products from multiple suppliers and immediately sorting them for outbound shipment without long-term storage. For example, a grocery retailer's distribution center may receive fresh produce from various farms and quickly transfer these goods to delivery trucks bound for individual stores. This process minimizes storage time, reduces inventory holding costs, and improves supply chain efficiency. Retailers use cross-docking to streamline product flow, particularly for perishable goods or high-demand items. In fast-fashion retail, a distribution center might cross-dock clothing shipments directly from manufacturers to stores based on real-time sales data. Data systems in these centers track incoming shipments and coordinate rapid sorting, facilitating faster turnover and maintaining product availability.

Table of Comparison

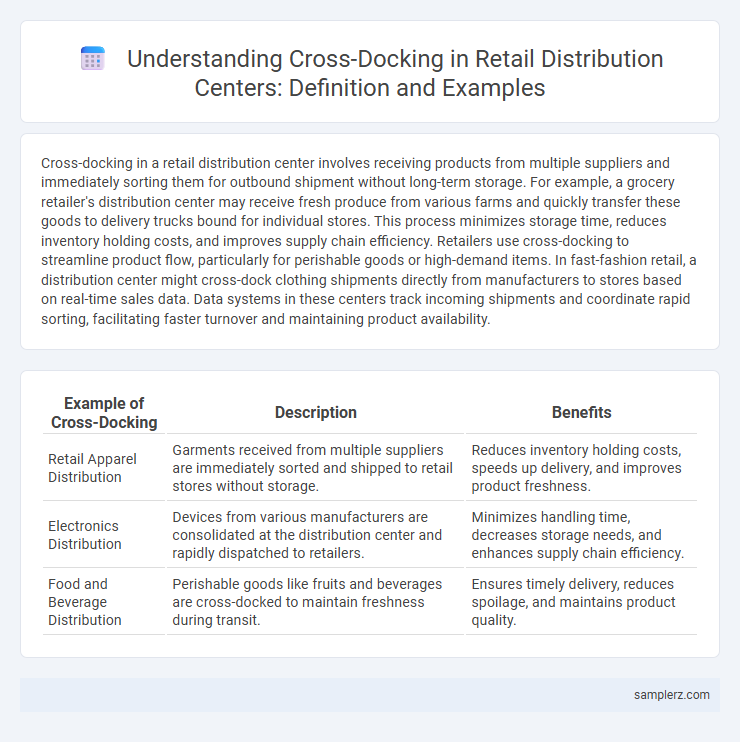

| Example of Cross-Docking | Description | Benefits |

|---|---|---|

| Retail Apparel Distribution | Garments received from multiple suppliers are immediately sorted and shipped to retail stores without storage. | Reduces inventory holding costs, speeds up delivery, and improves product freshness. |

| Electronics Distribution | Devices from various manufacturers are consolidated at the distribution center and rapidly dispatched to retailers. | Minimizes handling time, decreases storage needs, and enhances supply chain efficiency. |

| Food and Beverage Distribution | Perishable goods like fruits and beverages are cross-docked to maintain freshness during transit. | Ensures timely delivery, reduces spoilage, and maintains product quality. |

Introduction to Cross-Docking in Retail Distribution Centers

Cross-docking in retail distribution centers involves the direct transfer of products from inbound to outbound transportation with minimal or no storage time, significantly reducing inventory holding costs. For example, Walmart utilizes cross-docking to streamline its supply chain by receiving products from suppliers and immediately sorting them for delivery to stores, enhancing efficiency and reducing lead times. This method optimizes logistics by minimizing warehouse space usage and accelerating product flow from suppliers to retail shelves.

Key Benefits of Cross-Docking for Retailers

Cross-docking in retail distribution centers reduces inventory holding costs by minimizing storage time and enables faster product turnover, improving supply chain efficiency. It enhances order accuracy and streamlines logistics, leading to reduced transportation expenses and quicker delivery to stores. Retailers benefit from increased responsiveness to market demand and lower risk of stock obsolescence through real-time inventory management.

Step-by-Step Cross-Docking Process in Distribution Centers

Cross-docking in distribution centers involves the direct transfer of inbound products to outbound trucks with minimal storage time, enhancing efficiency and reducing inventory costs. The process begins with receiving goods from suppliers, followed by sorting and inspecting items according to customer orders. Finally, products are immediately loaded onto outbound transportation, enabling faster delivery and improved supply chain responsiveness.

Types of Cross-Docking Used in Retail

Cross-docking in retail distribution centers primarily involves three types: manufacturing cross-docking, where inbound shipments from suppliers are sorted directly to outbound trucks without storage; distributor cross-docking, which consolidates products from multiple suppliers for specific store deliveries; and transportation cross-docking, optimizing shipping routes by grouping products for distribution to various retail locations. Each type enhances inventory turnover rates and minimizes handling costs, significantly improving supply chain efficiency. Retailers leverage these methods to reduce lead times, decrease warehouse storage costs, and streamline product flow from supplier to store shelves.

Real-World Examples of Retail Cross-Docking Operations

Retail giants like Walmart implement cross-docking by receiving products from multiple suppliers and immediately sorting them for outbound trucks without long-term storage, reducing warehouse overhead. Amazon's distribution centers utilize cross-docking to expedite order fulfillment by synchronizing inbound shipments with customer orders, enabling quicker deliveries. This approach minimizes inventory holding costs and enhances supply chain efficiency, driving faster turnaround in retail distribution networks.

Major Retailers Successfully Utilizing Cross-Docking

Walmart employs cross-docking extensively in its distribution centers, minimizing inventory storage time and accelerating product flow to stores. Target's distribution network leverages cross-docking to streamline supply chain operations, reducing lead times and enhancing shelf availability. Costco integrates cross-docking strategies to efficiently manage high-volume shipments, ensuring rapid turnaround and cost savings in their distribution processes.

Technologies Enabling Efficient Cross-Docking

Advanced technologies such as real-time inventory management systems and automated sorting conveyors streamline cross-docking processes in distribution centers. RFID tagging enhances tracking accuracy, enabling faster handling and reduced errors. Integration of warehouse robotics and AI-driven analytics optimizes pallet movements and load planning, significantly improving operational efficiency.

Common Challenges in Cross-Docking Implementation

Cross-docking in retail distribution centers often faces challenges such as real-time inventory accuracy, which impacts efficient sorting and shipping processes. Limited dock door availability and tight scheduling constraints can cause bottlenecks, delaying product flow and increasing labor costs. Integration difficulties between warehouse management systems (WMS) and transportation management systems (TMS) further complicate seamless communication and coordination.

Cross-Docking vs Traditional Warehousing in Retail

Cross-docking in retail distribution centers minimizes storage time by directly transferring products from inbound to outbound trucks, enhancing inventory turnover and reducing handling costs. Unlike traditional warehousing, which involves prolonged storage and multiple stock movements, cross-docking accelerates product flow and responds faster to demand fluctuations. This streamlined process improves supply chain efficiency and lowers operational expenses in retail distribution networks.

Future Trends in Cross-Docking for Retail Distribution

Future trends in cross-docking for retail distribution emphasize advanced automation and AI-driven sorting systems that enhance real-time inventory management and reduce handling times. Integration of IoT devices facilitates seamless communication between suppliers, distribution centers, and retail outlets, optimizing supply chain visibility and efficiency. The rise of sustainable logistics practices promotes energy-efficient cross-docking operations, supporting both environmental goals and cost reduction strategies.

example of cross-docking in distribution center Infographic

samplerz.com

samplerz.com