Planogram variance in a hardware store occurs when the physical arrangement of products deviates from the established planogram, which is a visual guide for product placement. For example, hand tools such as hammers and screwdrivers may be misplaced on shelves intended for power tool accessories, leading to decreased product visibility and customer confusion. Data from store audits often reveal that 15-20% of hardware items are out of their designated locations, impacting sales and inventory accuracy. This variance affects inventory management and sales forecasting by distorting stock levels and customer purchasing patterns. Retail analytics show that correcting planogram compliance can increase category sales by up to 10% in hardware sectors. Implementing regular shelf audits with mobile scanning technology helps detect discrepancies, ensuring alignment with planograms and improving overall store performance.

Table of Comparison

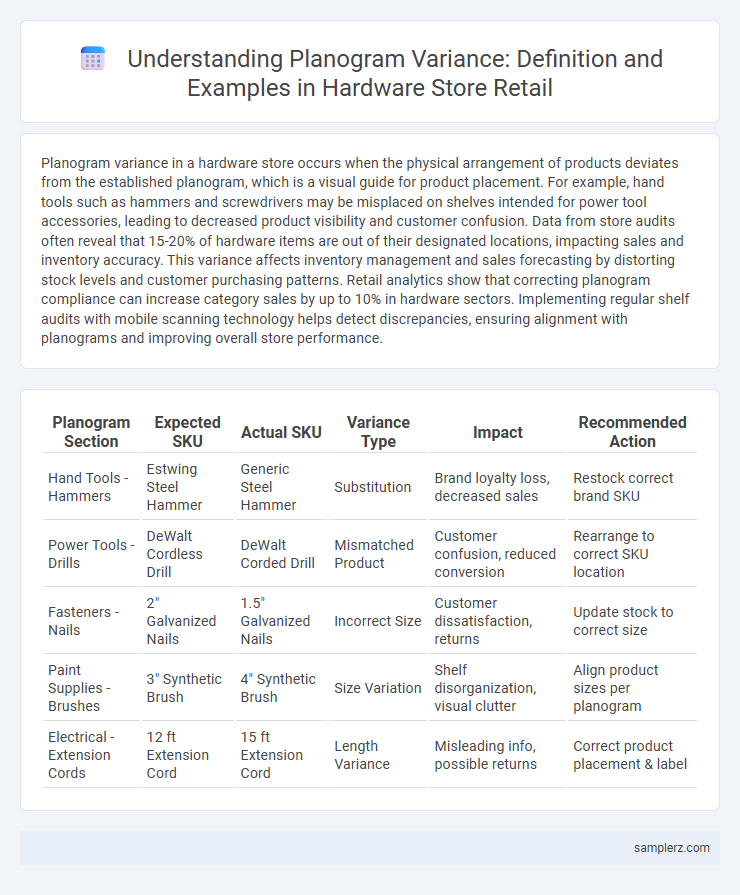

| Planogram Section | Expected SKU | Actual SKU | Variance Type | Impact | Recommended Action |

|---|---|---|---|---|---|

| Hand Tools - Hammers | Estwing Steel Hammer | Generic Steel Hammer | Substitution | Brand loyalty loss, decreased sales | Restock correct brand SKU |

| Power Tools - Drills | DeWalt Cordless Drill | DeWalt Corded Drill | Mismatched Product | Customer confusion, reduced conversion | Rearrange to correct SKU location |

| Fasteners - Nails | 2" Galvanized Nails | 1.5" Galvanized Nails | Incorrect Size | Customer dissatisfaction, returns | Update stock to correct size |

| Paint Supplies - Brushes | 3" Synthetic Brush | 4" Synthetic Brush | Size Variation | Shelf disorganization, visual clutter | Align product sizes per planogram |

| Electrical - Extension Cords | 12 ft Extension Cord | 15 ft Extension Cord | Length Variance | Misleading info, possible returns | Correct product placement & label |

Introduction to Planogram Variance in Hardware Stores

Planogram variance in hardware stores occurs when the actual product placement deviates from the prescribed shelf layout, impacting inventory management and customer experience. Common examples include misaligned SKU positioning, inconsistent facings, and unauthorized product substitutions that disrupt visual merchandising strategies. Accurate planogram compliance is critical for optimizing space utilization, improving sales performance, and maintaining brand consistency within hardware retail environments.

Common Causes of Planogram Variance in Retail Hardware

Planogram variance in retail hardware stores often results from inconsistent product placement, inaccurate shelf labeling, and frequent stockouts. Seasonal promotions and supplier delivery delays contribute to deviations from the predetermined shelf layout. Employee non-compliance with planogram guidelines and space constraints for bulky hardware items further exacerbate planogram inconsistencies.

Impact of Planogram Variance on Hardware Store Sales

Planogram variance in a hardware store often leads to misplaced products, reducing shelf visibility and causing customer frustration, which directly impacts sales by lowering purchase frequency. Misaligned inventory presentation disrupts the organized layout, making it difficult for customers to find essential items like power tools, fasteners, or plumbing supplies, resulting in lost revenue. Consistent planogram adherence enhances product accessibility, increases sales conversions, and improves overall customer satisfaction in hardware retail environments.

Tools Aisle: Example of Misaligned Pegboards

Misaligned pegboards in the Tools Aisle cause planogram variance by disrupting product placement, leading to uneven display of hand tools and power tools. Inconsistent peg hook spacing results in overcrowded sections or gaps, negatively impacting inventory visibility and customer browsing experience. Correcting pegboard alignment ensures optimal use of shelf space and maintains compliance with merchandising standards.

Seasonal Hardware Displays: Not Following Planograms

Seasonal hardware displays often experience planogram variance when store associates rearrange items based on perceived customer preferences, leading to inconsistent product placement and reduced sales efficiency. For example, holiday-themed tools and accessories may be scattered across aisles instead of grouped as specified, disrupting shopping flow and inventory management. Maintaining strict adherence to planograms during seasonal transitions is critical to optimize shelf space and enhance customer experience in hardware retail.

Fasteners Section: Overstocking vs. Understocking Issues

Overstocking in the Fasteners section of a hardware store leads to cluttered shelves, making it difficult for customers to locate specific items such as screws, nails, and bolts, while tying up valuable inventory space and increasing carrying costs. Understocking results in frequent stockouts of popular fasteners, causing lost sales and diminished customer satisfaction as contractors and DIY enthusiasts cannot complete their projects efficiently. Effective planogram management using sales data and inventory turnover rates helps balance stock levels, optimizing shelf space for high-demand fasteners and reducing waste from excess inventory.

Misplacement of Power Tools in Featured Endcaps

Misplacement of power tools in featured endcaps frequently occurs when drill sets are intermixed with unrelated accessories like paintbrushes, disrupting customer flow and reducing sales efficiency. Such planogram variance leads to diminished product visibility and confuses shoppers seeking specific power tools like cordless drills or impact drivers. Correct alignment with the planogram boosts average transaction value by guiding consumers directly to key items and improving inventory management.

Inconsistent Labeling of Paint Supplies on Shelves

In hardware stores, planogram variance frequently occurs due to inconsistent labeling of paint supplies on shelves, leading to customer confusion and stock mismanagement. Misaligned labels hinder efficient product identification, resulting in decreased sales of both premium and budget paint brands. Ensuring uniform labeling aligned with planogram standards optimizes shelf organization and improves inventory accuracy.

Consequences of Planogram Deviations in Hardware Retail

Planogram deviations in hardware stores often lead to misplaced tools and inventory discrepancies, resulting in increased stockouts and overstocks, which reduce sales efficiency. These inconsistencies disrupt customer shopping experiences by making it difficult to locate essential items like power drills or fasteners, ultimately decreasing customer satisfaction and loyalty. Furthermore, inaccurate product placement undermines store analytics and demand forecasting, causing inventory management challenges and higher operational costs.

Best Practices to Prevent Planogram Variance in Hardware Stores

Regularly auditing product placement against the approved planogram ensures consistency in hardware stores, minimizing planogram variance caused by misplaced or missing items. Implementing digital planogram tools with real-time updates and staff training on accurate shelf replenishment enhances adherence to layout standards. Clear labeling and use of planogram compliance software facilitate efficient monitoring, reducing discrepancies and improving overall inventory management.

example of planogram variance in hardware store Infographic

samplerz.com

samplerz.com