Planogram compliance in retail store audits involves verifying that product placements strictly follow the pre-designed schematic diagrams. Auditors check shelf layouts, product facings, and promotional displays to ensure alignment with the planogram, which optimizes space utilization and enhances customer experience. Data collected during these audits include compliance percentages, out-of-stock instances, and unauthorized product placements. The analysis of planogram compliance data helps retailers identify gaps in merchandising execution and improve inventory management. Retail chains often use mobile audit tools to capture real-time planogram adherence metrics and generate actionable insights. Maintaining high planogram compliance is critical for maximizing sales, improving visual appeal, and ensuring consistent brand presentation across multiple store locations.

Table of Comparison

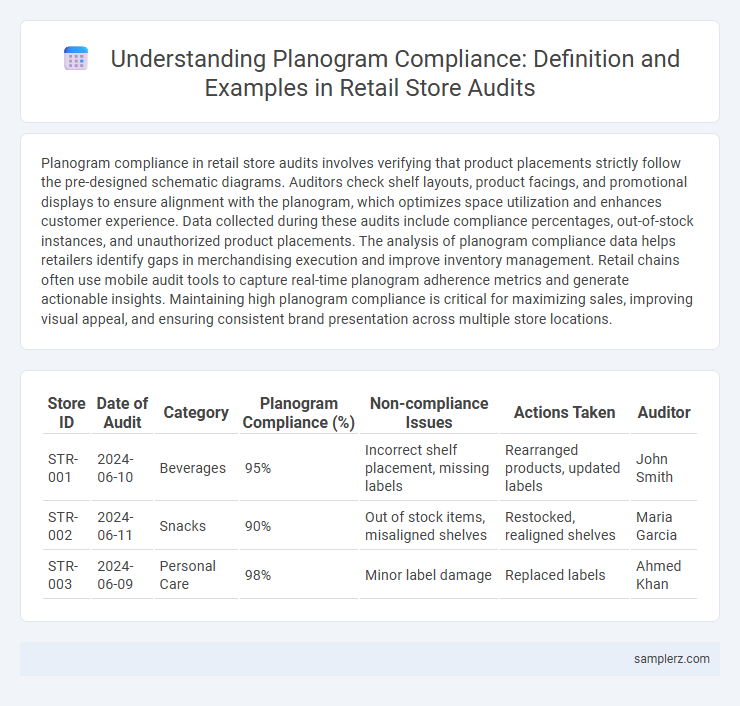

| Store ID | Date of Audit | Category | Planogram Compliance (%) | Non-compliance Issues | Actions Taken | Auditor |

|---|---|---|---|---|---|---|

| STR-001 | 2024-06-10 | Beverages | 95% | Incorrect shelf placement, missing labels | Rearranged products, updated labels | John Smith |

| STR-002 | 2024-06-11 | Snacks | 90% | Out of stock items, misaligned shelves | Restocked, realigned shelves | Maria Garcia |

| STR-003 | 2024-06-09 | Personal Care | 98% | Minor label damage | Replaced labels | Ahmed Khan |

Key Elements of Planogram Compliance in Retail Stores

Planogram compliance in retail store audits revolves around key elements such as product placement, shelf organization, and stock levels. Auditors verify that products are positioned according to the approved layout, ensuring facings and spacing align with brand standards. Accurate compliance improves inventory management, enhances shopper experience, and drives sales performance.

Real-World Examples of Planogram Compliance Audits

In a recent retail audit, a leading supermarket chain achieved 95% planogram compliance by using handheld scanners to verify shelf placements against digital blueprints, ensuring optimal product visibility and stock rotation. Another example includes an electronics retailer leveraging AI-powered image recognition technology to conduct rapid in-store planogram compliance checks, reducing manual errors and audit times by 40%. These real-world applications highlight the efficiency and accuracy improvements possible through integrating advanced tools in planogram compliance audits.

Common Planogram Compliance Issues Observed in Store Audits

Common planogram compliance issues observed in store audits include incorrect product placement, missing or misplaced promotional displays, and inconsistent shelf labeling. Retail audits frequently reveal stockouts or overstocking due to poor planogram adherence, leading to diminished product visibility and reduced sales. These compliance gaps often result from inadequate staff training or lack of real-time monitoring tools.

Best Practices for Achieving Planogram Compliance

Ensuring planogram compliance during store audits involves consistently verifying shelf placement and product arrangement against the established visual merchandising guidelines to maximize product visibility and sales. Best practices include training staff on the importance of planogram adherence, using mobile audit tools for real-time verification, and conducting frequent audits to promptly address discrepancies. Leveraging data analytics from these audits helps retailers optimize inventory management and enhance the overall shopping experience.

Impact of Planogram Compliance on Retail Sales Performance

Planogram compliance during store audits ensures product placement aligns with brand standards, directly influencing customer purchasing behavior. Studies indicate stores with high planogram adherence experience up to a 10-15% increase in sales due to enhanced product visibility and inventory management. Effective compliance reduces stockouts and improves shopper satisfaction, driving overall retail sales performance.

Tools and Technologies for Verifying Planogram Compliance

Planogram compliance in retail store audits is verified using tools such as mobile scanning devices and image recognition software that compare real-time shelf arrangements against digital planogram models. Advanced technologies like AI-powered analytics and shelf monitoring cameras enhance accuracy by detecting stock misplacements and out-of-stock items instantly. These tools ensure consistent visual merchandising, optimize shelf space utilization, and improve overall inventory management.

Case Study: Successful Planogram Compliance in Grocery Chains

A notable case study in grocery chains demonstrated 98% planogram compliance during store audits, resulting in increased product visibility and a 12% boost in sales for promoted items. By utilizing real-time shelf-scanning technology combined with trained auditors, these grocery retailers ensured accurate product placement and optimal inventory levels. Enhanced planogram adherence directly improved customer satisfaction and operational efficiency across 150+ store locations.

Steps for Conducting a Planogram Compliance Store Audit

Conducting a planogram compliance store audit involves examining shelf layouts to ensure merchandise placement aligns with the approved planogram, which enhances product visibility and maximizes sales potential. Auditors use checklists and digital tools to measure item quantities, shelf positioning, and signage accuracy against prescribed standards. Accurate documentation of discrepancies and timely reporting to store management enables corrective actions, maintaining consistent brand presentation across retail locations.

How Planogram Compliance Enhances Shopper Experience

Planogram compliance during store audits ensures products are placed precisely according to the designed layout, improving product visibility and ease of navigation for shoppers. Consistent adherence to planograms reduces customer frustration by making popular items easily accessible and promoting efficient store flow. Enhanced shopper experience resulting from planogram compliance directly increases customer satisfaction and boosts sales performance in retail environments.

Measuring the ROI of Planogram Compliance Initiatives

Measuring the ROI of planogram compliance initiatives involves analyzing sales uplift, inventory turnover rates, and customer engagement metrics within audited retail locations. Data from store audits reveal that stores with over 90% planogram compliance experience a 15-20% increase in category sales and a 10% reduction in out-of-stock incidents. Leveraging technology such as shelf-scanning and mobile audit tools enables precise monitoring and correlates compliance improvements directly with incremental revenue growth.

example of planogram compliance in store audit Infographic

samplerz.com

samplerz.com