Planogram compliance in pharmacy ensures that products are displayed according to predetermined layouts designed to maximize sales and improve customer experience. Pharmacies use planograms to arrange over-the-counter medications, personal care items, and health supplements, ensuring each product is positioned based on factors like category, brand, and sales velocity. Accurate execution of these layouts helps pharmacies maintain inventory control and enhance product visibility, directly impacting revenue and customer satisfaction. Data-driven audits measure planogram compliance by comparing actual shelf arrangements against the planogram's specifications. Technologies such as shelf-scanning devices and image recognition software enable real-time tracking and reporting of compliance rates. Higher compliance levels correlate with increased product turnover and reduced stockouts, making planogram adherence critical for pharmacies aiming to optimize retail operations and boost profitability.

Table of Comparison

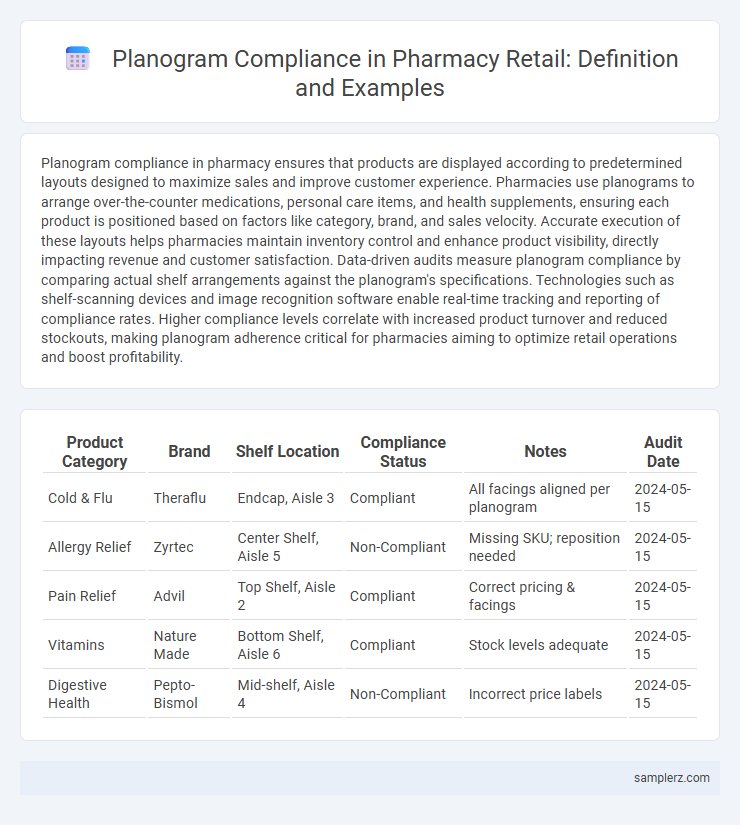

| Product Category | Brand | Shelf Location | Compliance Status | Notes | Audit Date |

|---|---|---|---|---|---|

| Cold & Flu | Theraflu | Endcap, Aisle 3 | Compliant | All facings aligned per planogram | 2024-05-15 |

| Allergy Relief | Zyrtec | Center Shelf, Aisle 5 | Non-Compliant | Missing SKU; reposition needed | 2024-05-15 |

| Pain Relief | Advil | Top Shelf, Aisle 2 | Compliant | Correct pricing & facings | 2024-05-15 |

| Vitamins | Nature Made | Bottom Shelf, Aisle 6 | Compliant | Stock levels adequate | 2024-05-15 |

| Digestive Health | Pepto-Bismol | Mid-shelf, Aisle 4 | Non-Compliant | Incorrect price labels | 2024-05-15 |

Importance of Planogram Compliance in Pharmacy Retail

Planogram compliance in pharmacy retail ensures optimal product placement that maximizes sales and improves inventory management. Adhering to planograms helps pharmacies maintain efficient aisle organization, reducing customer search time and enhancing the overall shopping experience. Accurate planogram execution also supports regulatory requirements for medication display and improves staff productivity by simplifying restocking processes.

Common Planogram Compliance Challenges in Pharmacies

Pharmacies often face planogram compliance challenges such as limited shelf space, frequent product updates, and staff turnover which impact accurate product placement. Inconsistent inventory management and variations in store layout further complicate adherence to planogram standards. Addressing these issues requires continuous staff training and robust auditing processes to maintain shelf organization and optimize product visibility.

Step-by-Step Planogram Implementation Example for OTC Medicines

Planogram compliance in pharmacy ensures OTC medicines are systematically arranged to maximize visibility and sales, following precise shelf space allocation and product facings. Step-by-step planogram implementation begins with accurately measuring shelf dimensions, followed by categorizing OTC products based on therapeutic use and brand hierarchy. Final placement is adjusted to maintain consistent facings, optimize eye-level positioning, and adhere to manufacturer guidelines, enhancing both customer experience and inventory management.

Analyzing Planogram Adherence: Visual Merchandising in Pharmacies

Analyzing planogram adherence in pharmacies involves systematically assessing product placement and shelf organization against predefined visual merchandising standards to optimize inventory visibility and sales performance. Utilizing shelf-scanning technology and compliance audits ensures pharmacists maintain accurate stock levels, improve customer experience, and enhance regulatory compliance. Effective planogram compliance contributes to streamlined workflow, minimized stockouts, and maximized profitability in retail pharmacy environments.

Case Study: Seasonal Product Placement Compliance

A pharmacy chain increased seasonal product sales by 25% through strict planogram compliance, ensuring all holiday-themed health supplements and wellness items were positioned according to the seasonal category layout. Store audits revealed a 95% adherence rate to the planogram during peak seasons, directly correlating with improved customer engagement and optimized inventory turnover. This case study demonstrates the critical role of accurate seasonal product placement in enhancing planogram effectiveness and driving revenue growth in retail pharmacies.

Best Practices for Planogram Compliance in Prescription Areas

Ensuring planogram compliance in pharmacy prescription areas involves regularly auditing shelf layouts to maintain accurate product placement according to manufacturer specifications, which enhances inventory control and customer safety. Utilizing digital planogram software helps track real-time compliance and alerts staff to discrepancies, reducing out-of-stock situations and prescription errors. Training pharmacy staff on standardized stocking procedures and the importance of visual merchandising supports consistent adherence to planogram standards, optimizing both operational efficiency and patient trust.

Technology Solutions for Pharmacy Planogram Monitoring

Technology solutions for pharmacy planogram monitoring utilize advanced imaging and AI-powered analytics to ensure accurate product placement and compliance. Smart shelf sensors and RFID technology provide real-time data on inventory and shelf conditions, enabling immediate corrective actions. These tools enhance operational efficiency, reduce out-of-stock incidents, and improve customer satisfaction in retail pharmacy environments.

Impact of Non-Compliance on Pharmacy Sales and Customer Experience

Non-compliance with planograms in pharmacies can lead to significant sales losses, as products placed incorrectly may reduce visibility and accessibility, directly impacting consumer purchasing decisions. This misalignment often causes customer frustration due to difficulty finding medications or preferred brands, diminishing overall store satisfaction and loyalty. Studies indicate that pharmacies adhering to strict planogram compliance experience up to 15% higher sales and improved customer retention rates compared to non-compliant stores.

Staff Training Methods for Enhancing Compliance Rates

Staff training methods in pharmacy retail emphasize hands-on workshops and simulation exercises to improve planogram compliance rates. Regular assessments and feedback sessions help staff understand the importance of accurate product placement for optimizing inventory visibility and customer experience. Integrating digital training modules with real-time compliance tracking accelerates learning and reinforces adherence to planogram standards.

Measuring and Auditing Planogram Compliance in Pharmacy Retail

Measuring and auditing planogram compliance in pharmacy retail involves regularly verifying product placement, shelf layout, and inventory alignment with the approved planogram using digital tools such as planogram software and mobile scanning devices. Key performance indicators include shelf share accuracy, out-of-stock rates, and product facings, which are tracked through audits to ensure optimal customer experience and regulatory compliance. Consistent auditing enhances inventory management, reduces shrinkage, and maximizes sales by maintaining proper product visibility and accessibility in pharmacy aisles.

example of planogram compliance in pharmacy Infographic

samplerz.com

samplerz.com