Cycle counting in an office supply store involves regularly auditing a subset of inventory items to ensure accurate stock levels. For example, a store might choose to count high-turnover products like printer paper, ink cartridges, and pens every week. This process helps identify discrepancies between physical counts and inventory records, enabling timely adjustments and minimizing stockouts or overstock situations. The cycle count data collected provides insights into purchasing patterns and potential shrinkage, improving inventory management efficiency. Store employees use handheld scanners to record quantities on shelves, which sync directly with the store's inventory management system. This method supports maintaining accurate inventory, enhancing customer satisfaction by ensuring popular office supplies remain available.

Table of Comparison

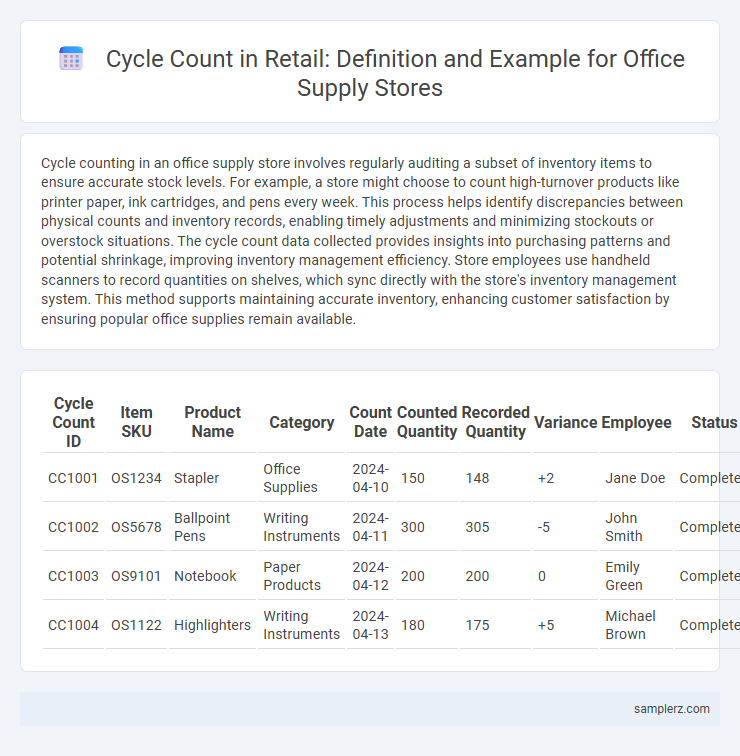

| Cycle Count ID | Item SKU | Product Name | Category | Count Date | Counted Quantity | Recorded Quantity | Variance | Employee | Status |

|---|---|---|---|---|---|---|---|---|---|

| CC1001 | OS1234 | Stapler | Office Supplies | 2024-04-10 | 150 | 148 | +2 | Jane Doe | Completed |

| CC1002 | OS5678 | Ballpoint Pens | Writing Instruments | 2024-04-11 | 300 | 305 | -5 | John Smith | Completed |

| CC1003 | OS9101 | Notebook | Paper Products | 2024-04-12 | 200 | 200 | 0 | Emily Green | Completed |

| CC1004 | OS1122 | Highlighters | Writing Instruments | 2024-04-13 | 180 | 175 | +5 | Michael Brown | Completed |

Introduction to Cycle Counting in Office Supply Stores

Cycle counting in office supply stores involves regularly scheduled inventory checks of high-turnover items such as pens, paper, and staples to maintain accurate stock levels. By systematically counting a subset of inventory daily or weekly, retailers minimize disruptions compared to full physical inventories and quickly identify discrepancies. This method enhances inventory accuracy, reduces stockouts, and supports efficient replenishment processes specific to office supply retail environments.

Importance of Accurate Inventory in Office Supply Retail

Cycle count in an office supply store ensures precise tracking of stock levels, reducing discrepancies and preventing stockouts or overstock situations. Accurate inventory management supports timely replenishment and enhances customer satisfaction by maintaining product availability. Regular cycle counts also improve financial reporting accuracy and optimize supply chain efficiency in the retail environment.

Step-by-Step Cycle Count Process Example

A cycle count in an office supply store begins by selecting a specific category, such as printer cartridges, for inventory verification. Employees physically count the items on the shelves and compare the quantities against the inventory management system to identify discrepancies. Any differences are documented, investigated, and corrected in the system to maintain accurate stock records and prevent stockouts or overstocking.

Tools and Technology for Office Supply Cycle Counts

Cycle counts in office supply stores utilize barcode scanners and inventory management software to accurately track stock levels of tools such as staplers, hole punches, and calculators. RFID technology further enhances efficiency by enabling real-time tracking and reducing manual errors during stock audits. Integrating mobile devices with cloud-based platforms allows employees to update inventory data instantly, ensuring optimal stock availability and minimizing discrepancies.

Common Office Supply Items Selected for Cycle Counting

Common office supply items selected for cycle counting in office supply stores typically include high-demand products such as printer paper, pens, staples, and sticky notes. These items are frequently restocked and have a high turnover rate, making accurate inventory levels critical for maintaining customer satisfaction and operational efficiency. Regular cycle counts of these essential supplies help prevent stockouts and ensure seamless business operations in a retail environment.

Frequency and Scheduling of Cycle Counts

In an office supply store, cycle counts are scheduled weekly for high-demand items like printer cartridges and paper reams, ensuring inventory accuracy without disrupting daily operations. Low-movement products such as specialty pens and binders undergo monthly counts to maintain stock integrity while optimizing labor resources. Frequent cycle counts reduce stock discrepancies, improve order fulfillment precision, and enhance overall inventory management efficiency.

Challenges Encountered in Office Supply Cycle Counting

Cycle counting in an office supply store often faces challenges such as inaccurate inventory records due to frequent product movement and small item sizes that are easily misplaced. Discrepancies between physical counts and system data arise from inconsistent counting procedures and human errors during stocktaking. Maintaining orderly stockrooms and implementing barcode scanning technology can mitigate these issues, yet fluctuating demand and high SKU variety continue to complicate accurate cycle counts.

Best Practices for Office Supply Store Cycle Counts

Perform cycle counts in an office supply store by scheduling regular inventory checks of high-turnover items like paper, pens, and toner cartridges to maintain accurate stock levels. Use barcode scanning technology to reduce counting errors and streamline data entry during each cycle count. Train employees on standardized counting procedures and document discrepancies immediately to ensure inventory accuracy and improve replenishment decisions.

Analyzing Cycle Count Discrepancies in Office Supplies

Cycle count discrepancies in an office supply store often arise from misplaced inventory or mis-scanned barcodes, necessitating thorough reconciliation between physical counts and inventory management systems. Detailed analysis of cycle count data reveals patterns in stock variances, highlighting frequently affected SKUs such as printer cartridges and paper reams that demand closer monitoring. Accurate identification and correction of these discrepancies improve inventory accuracy, reduce stockouts, and enhance overall operational efficiency in retail office supply management.

Impact of Regular Cycle Counts on Office Supply Retail Performance

Regular cycle counts in office supply stores significantly reduce inventory discrepancies, ensuring accurate stock levels and minimizing lost sales due to out-of-stock items. Improved inventory accuracy enhances reorder efficiency, allowing timely restocking of high-demand products like printer paper and ink cartridges. Consistent cycle counting also boosts customer satisfaction by maintaining product availability, directly impacting overall store profitability and operational performance.

example of cycle count in office supply store Infographic

samplerz.com

samplerz.com