Lean manufacturing focuses on minimizing waste and maximizing efficiency in production processes. Toyota is a prime example, implementing the Toyota Production System to streamline operations, reduce inventory, and improve product quality. This approach uses techniques like Just-In-Time (JIT) production and continuous improvement (Kaizen) to enhance overall productivity. Another example is Nike, which employs lean principles in its footwear manufacturing. The company optimizes supply chain management and reduces excess materials to cut costs and shorten production cycles. By leveraging lean manufacturing, Nike achieves faster turnaround times while maintaining high standards of product excellence.

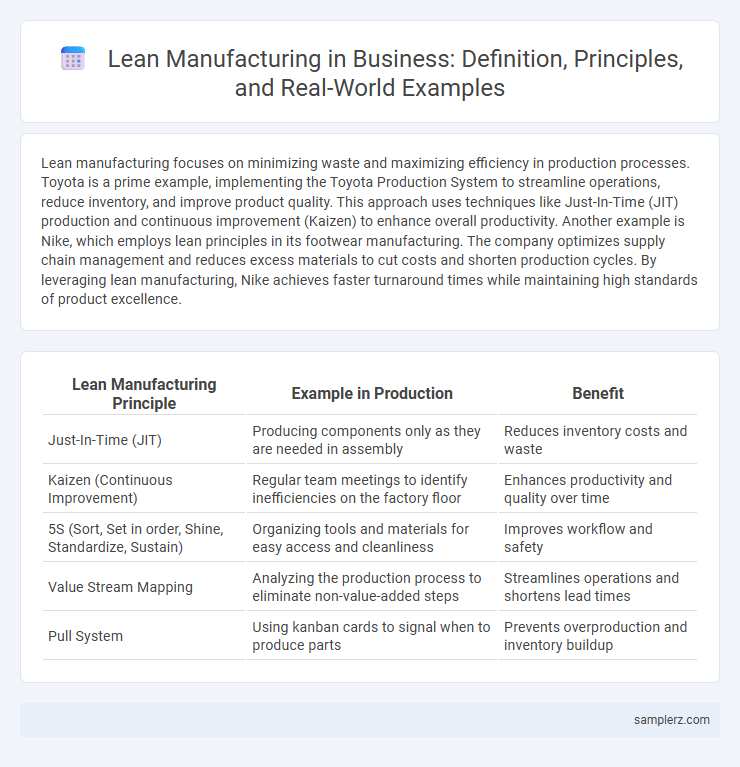

Table of Comparison

| Lean Manufacturing Principle | Example in Production | Benefit |

|---|---|---|

| Just-In-Time (JIT) | Producing components only as they are needed in assembly | Reduces inventory costs and waste |

| Kaizen (Continuous Improvement) | Regular team meetings to identify inefficiencies on the factory floor | Enhances productivity and quality over time |

| 5S (Sort, Set in order, Shine, Standardize, Sustain) | Organizing tools and materials for easy access and cleanliness | Improves workflow and safety |

| Value Stream Mapping | Analyzing the production process to eliminate non-value-added steps | Streamlines operations and shortens lead times |

| Pull System | Using kanban cards to signal when to produce parts | Prevents overproduction and inventory buildup |

Introduction to Lean Manufacturing in Production

Lean manufacturing in production emphasizes eliminating waste to improve efficiency and product quality. Companies like Toyota implement techniques such as just-in-time inventory and continuous improvement (Kaizen) to streamline processes and reduce costs. These methods result in faster production cycles, lower inventory levels, and enhanced customer satisfaction.

Key Principles of Lean Manufacturing

Lean manufacturing emphasizes eliminating waste through continuous improvement, just-in-time inventory, and maintaining high-quality standards in production processes. Key principles include value stream mapping to identify inefficiencies, creating flow by minimizing interruptions, and implementing pull systems to match production with customer demand. These strategies enhance productivity, reduce costs, and improve overall operational efficiency in manufacturing environments.

Toyota Production System: The Original Lean Example

The Toyota Production System (TPS) exemplifies lean manufacturing by minimizing waste through just-in-time production and jidoka (automation with a human touch). TPS integrates continuous improvement (kaizen) and respect for people, resulting in higher efficiency and quality in automotive production. This system's emphasis on standardization and employee empowerment has revolutionized global manufacturing practices.

Lean Implementation in Automotive Industry

Lean implementation in the automotive industry emphasizes waste reduction and continuous improvement through techniques such as Just-In-Time (JIT) production and Kanban systems. Toyota's Production System (TPS) serves as a prime example, focusing on eliminating overproduction, minimizing inventory, and streamlining workflow to enhance efficiency. These practices lead to higher product quality, reduced lead times, and significant cost savings for manufacturers.

Just-In-Time Production: Real-World Applications

Just-In-Time (JIT) production significantly reduces inventory costs by synchronizing raw material orders with production schedules, as exemplified by Toyota's streamlined assembly line. Companies like Dell implement JIT to customize computer manufacturing, lowering waste and accelerating delivery. Real-world applications demonstrate how JIT enhances efficiency, minimizes excess stock, and optimizes supply chain responsiveness in competitive business environments.

Lean Manufacturing in Electronics Production

Lean manufacturing in electronics production streamlines assembly lines by reducing waste through techniques like Just-In-Time (JIT) inventory and continuous flow processes. Companies such as Intel implement value stream mapping to identify bottlenecks and improve cycle time, enhancing product quality while minimizing costs. Utilizing Kaizen events and standardized work procedures, electronics manufacturers consistently boost efficiency and reduce defect rates.

Case Study: Lean Practices in Food Processing

A prominent example of lean manufacturing in food processing is the case of a leading dairy producer that implemented value stream mapping to identify and eliminate waste in its bottling line. By adopting Just-In-Time inventory and continuous flow techniques, the company reduced production lead time by 35% and improved overall equipment effectiveness (OEE) by 20%. These lean practices resulted in significant cost savings and enhanced product quality, demonstrating the impact of lean principles in the food production industry.

Waste Reduction Techniques in Manufacturing

Lean manufacturing employs waste reduction techniques such as Just-In-Time (JIT) production, which minimizes inventory costs by producing only what is needed, when it is needed. Value Stream Mapping (VSM) identifies and eliminates non-value-added activities within the production process, streamlining workflows and reducing lead times. Continuous improvement practices, like Kaizen, engage employees in ongoing efforts to eliminate inefficiencies and enhance product quality.

Continuous Improvement (Kaizen) Success Stories

Toyota's implementation of lean manufacturing through continuous improvement (Kaizen) revolutionized production efficiency by reducing waste and enhancing workflow productivity. General Electric adopted Kaizen principles, leading to significant cost savings and quality improvements across multiple manufacturing plants. Nike integrated continuous improvement strategies to streamline its supply chain, resulting in faster production cycles and increased responsiveness to market demands.

Benefits and Challenges of Lean in Modern Production

Lean manufacturing optimizes production by minimizing waste and enhancing workflow efficiency, leading to significant cost savings and faster delivery times. Benefits include improved product quality, increased employee engagement, and greater flexibility to respond to market changes. Challenges involve sustaining continuous improvement efforts, managing cultural resistance, and balancing just-in-time inventory with supply chain disruptions.

example of lean manufacturing in production Infographic

samplerz.com

samplerz.com