A prominent example of a keiretsu in the automobile industry is Toyota Motor Corporation's network. Toyota's keiretsu consists of close relationships with suppliers such as Denso, Aisin Seiki, and Toyota Tsusho, enabling streamlined production and innovation. This interconnected structure supports stable supply chains and collaborative technology development. These entities often hold cross-shareholdings, reinforcing long-term partnerships and financial stability. Data from industry reports indicate that such networks reduce risks related to supply disruptions and improve efficiency in manufacturing processes. Toyota's keiretsu exemplifies how integrated business groups can optimize operations and maintain competitive advantages in the automotive sector.

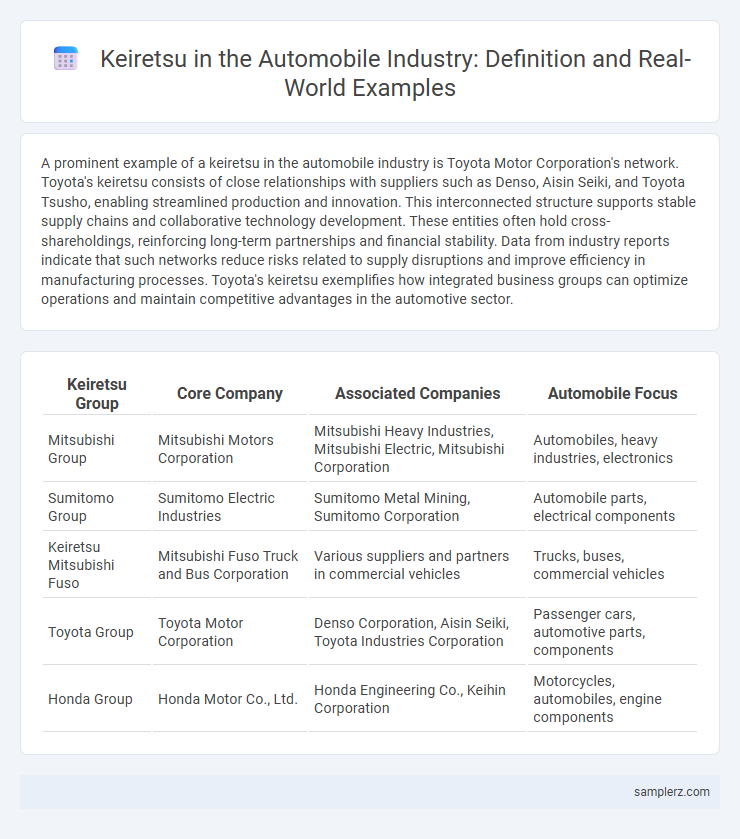

Table of Comparison

| Keiretsu Group | Core Company | Associated Companies | Automobile Focus |

|---|---|---|---|

| Mitsubishi Group | Mitsubishi Motors Corporation | Mitsubishi Heavy Industries, Mitsubishi Electric, Mitsubishi Corporation | Automobiles, heavy industries, electronics |

| Sumitomo Group | Sumitomo Electric Industries | Sumitomo Metal Mining, Sumitomo Corporation | Automobile parts, electrical components |

| Keiretsu Mitsubishi Fuso | Mitsubishi Fuso Truck and Bus Corporation | Various suppliers and partners in commercial vehicles | Trucks, buses, commercial vehicles |

| Toyota Group | Toyota Motor Corporation | Denso Corporation, Aisin Seiki, Toyota Industries Corporation | Passenger cars, automotive parts, components |

| Honda Group | Honda Motor Co., Ltd. | Honda Engineering Co., Keihin Corporation | Motorcycles, automobiles, engine components |

Introduction to Keiretsu in the Automobile Industry

Keiretsu in the automobile industry exemplifies tightly-knit business networks where manufacturers like Toyota collaborate closely with suppliers, distributors, and financial institutions to streamline production and innovation. This interconnected ecosystem allows for efficient resource sharing, long-term partnerships, and reduced transaction costs, boosting competitive advantage. The Toyota Group, a prominent keiretsu, demonstrates how such alliances enhance supply chain stability and technological development in automotive manufacturing.

Historical Background of Keiretsu in Japan

The keiretsu system in Japan's automobile industry, exemplified by Toyota Group, originated post-World War II to rebuild the economy through close cooperation among manufacturers, suppliers, and banks. This network facilitated long-term partnerships, shared technology, and capital support, strengthening industrial stability and innovation. The keiretsu structure significantly influenced the global competitiveness of Japanese automakers by fostering trust and integrated supply chains.

Structure of Automobile Keiretsu Networks

Automobile keiretsu networks consist of tightly interwoven relationships between manufacturers, suppliers, and distributors characterized by cross-shareholding and long-term partnerships. In Japan, major automakers like Toyota and Honda form central nodes surrounded by tiered suppliers providing components, fostering efficient supply chain integration and innovation. This hierarchical structure promotes stability, trust, and mutual investment, enhancing competitive advantage within the automotive industry.

Toyota’s Keiretsu Model: A Leading Example

Toyota's Keiretsu model exemplifies a tightly-knit network of suppliers and manufacturers that fosters long-term partnerships, supply chain stability, and innovation in the automobile industry. This structure integrates key suppliers like Aisin Seiki and Denso, enabling efficient coordination and quality control across production processes. The collaborative approach reduces costs and enhances product development, setting a benchmark for other automakers worldwide.

Nissan’s Keiretsu Relationships and Strategy

Nissan's keiretsu strategy revolves around close collaborations with suppliers such as Sumitomo and Mitsubishi, fostering long-term partnerships that enhance supply chain stability and innovation. These interconnected relationships enable Nissan to streamline production processes, reduce costs, and maintain high-quality standards in automobile manufacturing. By leveraging keiretsu networks, Nissan strengthens its competitive edge through shared technology development and coordinated business practices within Japan's automotive industry.

Honda’s Collaborative Keiretsu Partnerships

Honda's collaborative keiretsu partnerships exemplify a tightly integrated network of suppliers and manufacturers focused on innovation and efficiency. Key partners such as Denso, Showa Corporation, and Keihin supply critical components like electronics, suspension systems, and fuel delivery mechanisms, ensuring seamless coordination and quality control. This ecosystem fosters mutual investment, technology sharing, and long-term relationships that enhance Honda's competitive advantage in the global automobile market.

Mitsubishi Motors: Keiretsu Influence and Growth

Mitsubishi Motors exemplifies keiretsu influence through its strategic partnerships with core suppliers and allied companies, fostering innovation and operational efficiency in automobile manufacturing. The keiretsu structure enables seamless coordination in research, development, and supply chain management, driving Mitsubishi Motors' competitive growth in the global automotive market. This network-centric approach enhances resilience and adaptability, positioning Mitsubishi Motors as a key player within Japan's industrial ecosystem.

Supplier Integration within Automobile Keiretsu

Toyota's keiretsu exemplifies supplier integration by fostering long-term relationships with key suppliers such as Denso and Aisin Seiki, enhancing parts quality and innovation. This close collaboration enables synchronized production schedules and shared technological developments, resulting in reduced costs and increased efficiency. Supplier integration within Toyota's keiretsu structure drives continuous improvement and maintains competitive advantage in the automobile industry.

Advantages of Keiretsu for Automobile Manufacturers

Keiretsu networks, such as the Toyota Group, provide automobile manufacturers with stable supply chains and improved coordination among suppliers, enabling consistent quality and innovation. These close partnerships reduce transaction costs and foster long-term collaborations, enhancing efficiency and responsiveness to market demands. The integrated structure also supports risk-sharing and resource pooling, which strengthens competitive advantage in the global automotive industry.

Future Trends of Keiretsu in the Global Automotive Sector

Toyota's keiretsu exemplifies future trends in the global automotive sector by fostering integrated supplier networks and promoting innovation in electric and autonomous vehicle technologies. Collaborative partnerships within this group enable rapid adaptation to evolving market demands and the integration of sustainable practices. Emphasizing digital transformation and supply chain resilience positions Toyota's keiretsu as a model for the future of automotive industry alliances.

example of keiretsu in automobile Infographic

samplerz.com

samplerz.com