In the mining industry, cableways play a crucial role in transporting ore and personnel across challenging terrains. One well-known example is the ropeway system used in the Cerro Rico mine in Bolivia, where large buckets attached to cables move extracted minerals efficiently over steep and rugged landscapes. This system reduces the need for extensive road networks and minimizes environmental impact while maintaining high transport capacity. Cableways offer significant advantages in mining operations, including increased safety and reduced operational costs. By suspending loads above ground, they avoid interference with ground-level obstacles and reduce risks associated with traditional vehicle transport. Modern cableway technology incorporates advanced materials and automation, enhancing reliability and throughput in mining environments worldwide.

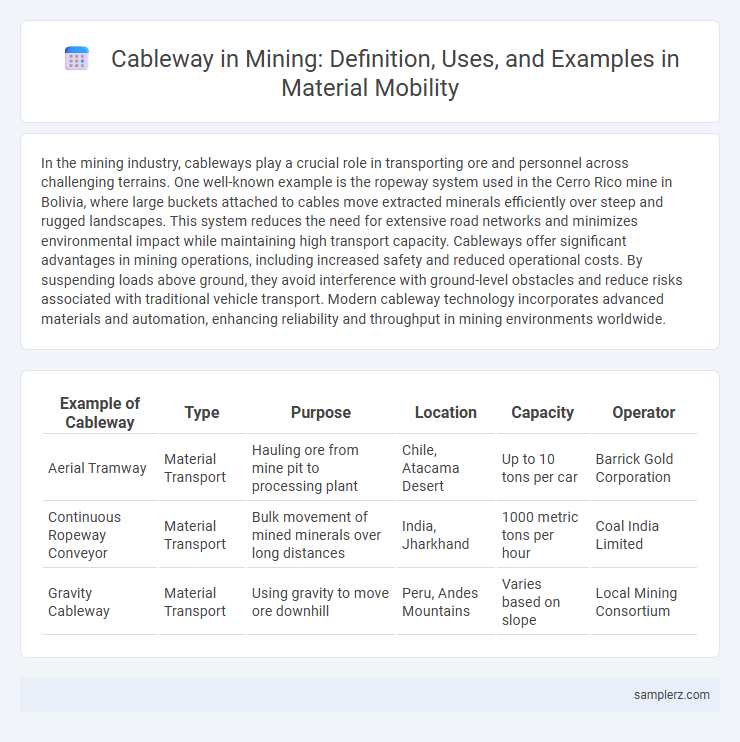

Table of Comparison

| Example of Cableway | Type | Purpose | Location | Capacity | Operator |

|---|---|---|---|---|---|

| Aerial Tramway | Material Transport | Hauling ore from mine pit to processing plant | Chile, Atacama Desert | Up to 10 tons per car | Barrick Gold Corporation |

| Continuous Ropeway Conveyor | Material Transport | Bulk movement of mined minerals over long distances | India, Jharkhand | 1000 metric tons per hour | Coal India Limited |

| Gravity Cableway | Material Transport | Using gravity to move ore downhill | Peru, Andes Mountains | Varies based on slope | Local Mining Consortium |

Introduction to Cableway Systems in Mining

Cableway systems in mining are advanced transportation solutions designed to move ore, equipment, and personnel across challenging terrains efficiently. These aerial ropeways consist of suspended cables and carriers, reducing the need for road construction and minimizing environmental impact. Employed worldwide, cableways enhance operational mobility by providing rapid, reliable access to remote mining sites.

Historical Evolution of Mining Cableways

Mining cableways trace back to the early 20th century, revolutionizing ore transportation across rugged terrains. The introduction of aerial ropeways enabled efficient movement of minerals from inaccessible mining sites to processing areas, significantly reducing reliance on traditional rail or road methods. Advances in cable technology and motorized systems throughout the decades enhanced load capacity and operational reliability, shaping modern mining logistics.

Key Components of Mining Cableway Technology

Mining cableway technology relies on key components such as robust steel cables capable of supporting heavy loads, durable carriers or buckets designed to transport extracted materials efficiently, and motorized winches that control the movement and tension of the cables. Advanced braking systems and tensioning devices ensure safety and stability during operation, while support towers and anchor points provide structural integrity across uneven terrain. Integration of automated control systems enhances precision and operational efficiency in mining cableway transport.

Advantages of Cableways in Mining Operations

Cableways in mining operations offer significant advantages such as efficient transportation of ore and materials over difficult terrains, reducing the need for extensive road construction and minimizing environmental impact. Their ability to operate continuously in harsh weather conditions enhances operational reliability and reduces downtime. Moreover, cableways lower labor costs and improve safety by limiting the exposure of workers to hazardous ground conditions.

Notable Global Examples of Mining Cableways

Notable global examples of mining cableways include the Manitou Incline in Colorado, USA, which was originally used for ore transport from mines in the early 20th century. The cableway system in the Copperbelt region of Zambia efficiently moves extracted copper ore across steep terrains to processing plants, significantly reducing transportation time. In Chile's Chuquicamata mine, aerial cableways transport massive quantities of copper ore across rugged landscapes, highlighting the technology's importance in modern mining logistics.

Case Study: Aerial Tramways in Copper Mining

Aerial tramways play a crucial role in copper mining by enabling efficient transportation of ore across rugged terrain where traditional roadways are impractical. The El Teniente copper mine in Chile exemplifies this, utilizing an extensive network of cable cars to move large quantities of ore swiftly while minimizing environmental impact. This cableway system dramatically reduces operational costs and enhances safety by limiting vehicle traffic in hazardous zones.

Innovations in Mining Cableway Design

Innovations in mining cableway design have significantly enhanced operational efficiency and safety, incorporating advanced materials such as high-tensile synthetic ropes that reduce maintenance and increase load capacity. Modern cableways integrate IoT sensors and automated control systems to monitor real-time stress, wear, and environmental conditions, enabling predictive maintenance and minimizing downtime. These advancements contribute to sustainable mining practices by reducing energy consumption and environmental impact during mineral transportation in rugged terrains.

Safety Protocols for Cableway Use in Mines

Effective safety protocols for cableway use in mining include regular inspection of cables, mechanical components, and securing devices to prevent failures. Operators must undergo specialized training in emergency procedures, load management, and communication systems to ensure safe transport of personnel and materials. Implementation of real-time monitoring technologies and strict adherence to load limits significantly reduce the risk of accidents and enhance overall operational safety.

Environmental Impact of Cableway Mining Systems

Cableway mining systems demonstrate significant environmental advantages by minimizing land disturbance compared to traditional hauling methods, reducing soil erosion and habitat fragmentation in mining areas. Their elevated transport reduces dust emissions and lowers fuel consumption, contributing to decreased greenhouse gas emissions and improved air quality. Efficient use of cableway technology supports sustainable mining practices by limiting the carbon footprint and preserving surrounding ecosystems.

Future Trends for Cableways in the Mining Industry

Emerging cableway technologies in mining leverage autonomous control systems and real-time monitoring to enhance operational efficiency and safety. Integration of renewable energy sources, such as solar-powered cableways, reduces environmental impact and operational costs. Future trends emphasize modular designs for rapid deployment and scalability across diverse mining terrains.

example of cableway in mining Infographic

samplerz.com

samplerz.com