Magnetolev technology, or magnetic levitation, is a pivotal innovation in high-speed rail systems, utilizing electromagnetic forces to lift and propel trains without direct contact with the tracks. This technology reduces friction and enables trains to reach speeds exceeding 600 kilometers per hour. Entities like the Shanghai Maglev Train exemplify the application of magnetolev, showcasing advancements in urban and intercity mobility. Data from operational magnetolev trains indicate significant energy efficiency compared to traditional rail systems, with reduced maintenance costs due to the lack of physical contact between train and track. The technology relies on superconducting magnets and precise control systems to maintain stability and safety at high velocities. Continuous improvements in magnetolev components and track design contribute to expanding its use in high-speed rail networks globally.

Table of Comparison

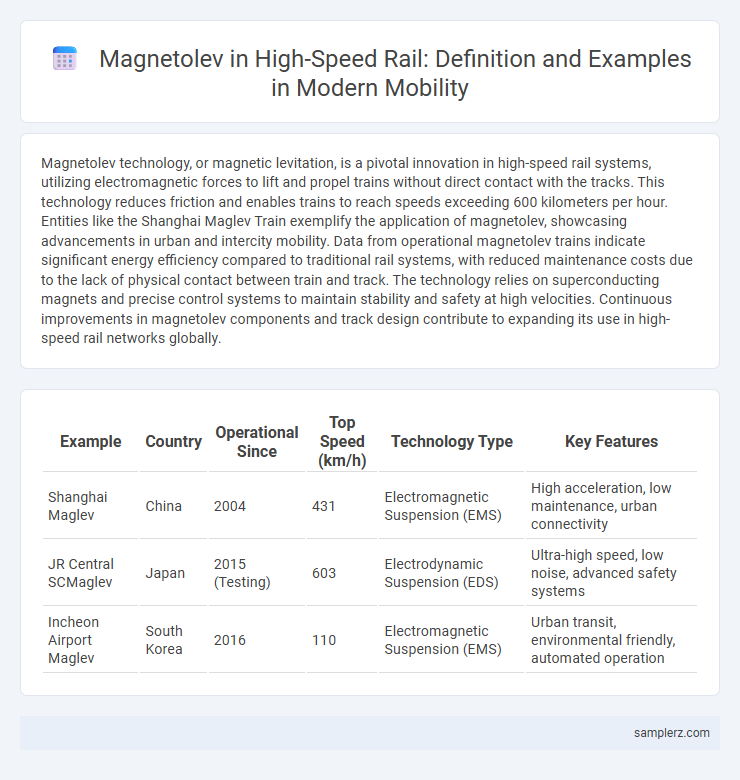

| Example | Country | Operational Since | Top Speed (km/h) | Technology Type | Key Features |

|---|---|---|---|---|---|

| Shanghai Maglev | China | 2004 | 431 | Electromagnetic Suspension (EMS) | High acceleration, low maintenance, urban connectivity |

| JR Central SCMaglev | Japan | 2015 (Testing) | 603 | Electrodynamic Suspension (EDS) | Ultra-high speed, low noise, advanced safety systems |

| Incheon Airport Maglev | South Korea | 2016 | 110 | Electromagnetic Suspension (EMS) | Urban transit, environmental friendly, automated operation |

Introduction to Magnetolev Technology in High-Speed Rail

Magnetolev technology in high-speed rail utilizes magnetic levitation to eliminate friction between the train and tracks, enabling speeds exceeding 600 km/h. This technology employs powerful electromagnets for both lift and propulsion, offering a quieter, smoother ride with reduced maintenance compared to traditional rail systems. Its implementation in projects like Japan's SCMaglev and China's Shanghai Maglev demonstrates the potential for significant advancements in rapid, energy-efficient transportation.

Historical Development of Magnetic Levitation Trains

Magnetic levitation (maglev) trains emerged in the 1960s with pioneering experiments in Germany and Japan, marking significant milestones in high-speed rail innovation. The Transrapid project in Germany and the SCMaglev development in Japan demonstrated leaps in magnetic propulsion technology, enabling speeds beyond conventional rail limits. These advancements laid the groundwork for modern maglev systems, showcasing reduced friction and increased efficiency in urban and intercity transport.

The Science Behind Magnetolev in Rail Systems

Magnetolevitation in high-speed rail relies on powerful electromagnets creating magnetic fields that lift the train above the tracks, eliminating friction and enabling speeds exceeding 600 km/h. Superconducting magnets generate the intense magnetic forces required for stable levitation and guidance, while controlled feedback systems maintain precise distances between train and guideway. This technology drastically reduces mechanical wear and energy consumption compared to conventional rail systems, making magnetolev an efficient solution for ultra-fast, smooth transportation.

Key Advantages of Magnetolev for High-Speed Transportation

Magnetolev technology enables frictionless travel by levitating trains above tracks, significantly reducing wear and energy consumption. High-speed rail systems using magnetolev achieve acceleration rates exceeding conventional trains, with top speeds surpassing 600 km/h. Enhanced stability and low noise levels improve passenger comfort and safety, making magnetolev an ideal solution for efficient long-distance transportation.

Notable Magnetolev High-Speed Rail Projects Worldwide

Shanghai Maglev Train in China operates at speeds up to 431 km/h using electromagnetic suspension technology, exemplifying cutting-edge magnetolev high-speed rail. Japan's SCMaglev, reaching speeds over 500 km/h during tests, utilizes superconducting magnets for ultra-fast travel on the Chuo Shinkansen line. Germany's Transrapid project demonstrated advanced linear motor propulsion and precise levitation control, influencing global magnetolev system designs.

Case Study: Shanghai Maglev Train System

The Shanghai Maglev Train System operates using electromagnetic suspension technology, reaching speeds up to 431 km/h, making it the fastest commercial high-speed maglev in the world. Utilizing magnetic levitation, the train eliminates wheel-rail friction, enhancing energy efficiency and reducing maintenance costs. The system's 30.5 km route between Pudong International Airport and Longyang Road Station showcases the viability of maglev technology for urban transit and rapid airport connectivity.

Magnetolev versus Conventional High-Speed Rail

Magnetolev technology, such as Japan's SCMaglev, uses magnetic levitation to eliminate friction, enabling speeds over 600 km/h compared to conventional high-speed rails like the Shinkansen, which typically reach maximum speeds around 320 km/h. The lack of physical contact between train and track reduces wear and maintenance, providing smoother acceleration and deceleration. Despite higher infrastructure costs, magnetolev systems offer significant energy efficiency and noise reduction advantages over traditional steel-wheel-on-rail technology.

Environmental Impact of Magnetolev Trains

Magnetolev trains significantly reduce carbon emissions compared to traditional diesel-powered trains, as they operate on electric power and produce zero direct pollution. The aerodynamic design and frictionless levitation contribute to lower energy consumption, making these high-speed trains more sustainable. By minimizing noise pollution and relying on renewable energy sources, magnetolev systems support greener transportation infrastructure with a reduced environmental footprint.

Technological Innovations Driving Magnetolev Adoption

Advanced magnetic levitation technology in high-speed rail employs superconducting magnets and precise electromagnetic control systems to minimize friction and enhance stability. Cutting-edge innovations such as cryogenic cooling and adaptive levitation magnets enable speeds exceeding 600 km/h while reducing energy consumption. Integrating AI-driven diagnostics and real-time modulation further boosts efficiency and safety in magnetolev train operations.

Future Prospects of Magnetolev in Global Mobility

Magnetolev technology in high-speed rail offers transformative potential for global mobility by enabling frictionless travel at speeds exceeding 600 km/h, significantly reducing travel time and energy consumption. Future developments focus on expanding magnetolev networks worldwide, integrating advanced superconducting magnets and AI-driven control systems to enhance stability, safety, and efficiency. This technology promises to revolutionize urban connectivity and international transportation by fostering sustainable, high-capacity transit solutions.

example of magnetolev in high-speed rail Infographic

samplerz.com

samplerz.com