Omnidirectional wheels, also known as mecanum wheels, are commonly used in robotics to enable movement in any direction without changing the robot's orientation. These wheels consist of a series of rollers attached at an angle around the circumference, allowing a robot to move forward, backward, sideways, and diagonally with precise control. An example of this technology is found in the Killough platform, a robot design that utilizes three omnidirectional wheels to achieve smooth multidirectional mobility. In practical applications, omnidirectional wheels improve maneuverability in tight spaces and complex environments, making them ideal for service robots and automated guided vehicles (AGVs). The Sphero robot ball is another example using similar principles, although it employs internal omnidirectional mechanisms rather than external wheels. Data from robotic mobility studies show that omnidirectional wheels enhance navigation efficiency by reducing the need for turning maneuvers, thereby increasing operational speed and accuracy.

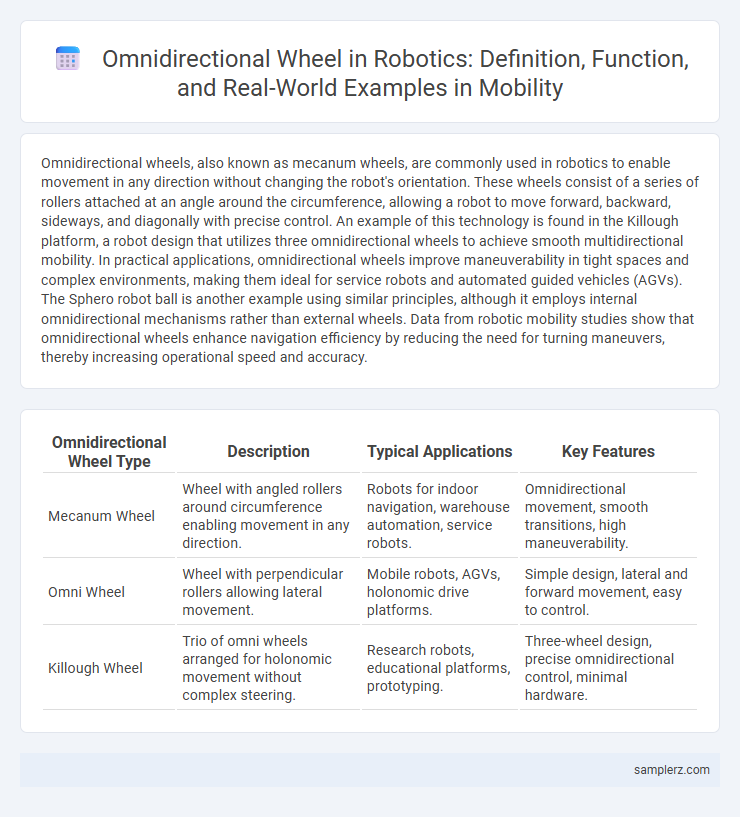

Table of Comparison

| Omnidirectional Wheel Type | Description | Typical Applications | Key Features |

|---|---|---|---|

| Mecanum Wheel | Wheel with angled rollers around circumference enabling movement in any direction. | Robots for indoor navigation, warehouse automation, service robots. | Omnidirectional movement, smooth transitions, high maneuverability. |

| Omni Wheel | Wheel with perpendicular rollers allowing lateral movement. | Mobile robots, AGVs, holonomic drive platforms. | Simple design, lateral and forward movement, easy to control. |

| Killough Wheel | Trio of omni wheels arranged for holonomic movement without complex steering. | Research robots, educational platforms, prototyping. | Three-wheel design, precise omnidirectional control, minimal hardware. |

Introduction to Omnidirectional Wheels in Robotics

Omnidirectional wheels, also known as omni wheels, enable robots to move freely in any direction without changing their orientation, significantly enhancing maneuverability. These wheels consist of a central hub with multiple rollers mounted around its circumference, allowing for smooth lateral, diagonal, and rotational movements. Commonly used in mobile robots and automated guided vehicles, omnidirectional wheels improve navigation efficiency in complex environments.

Key Features of Omnidirectional Wheels

Omnidirectional wheels, also known as mecanum or omni wheels, enable robots to move smoothly in any direction without changing their orientation. Key features include multiple rollers mounted at specific angles around the wheel circumference, which provide lateral movement and precision maneuverability. These wheels enhance robot agility in tight spaces, facilitating complex navigation patterns essential for advanced robotic mobility systems.

Common Types of Omnidirectional Wheels Used in Robots

Omnidirectional wheels in robotics include common types such as Mecanum wheels, which feature angled rollers allowing movement in multiple directions without changing the wheel orientation, and omni wheels, characterized by perpendicular rollers around the wheel circumference enabling lateral and forward motion simultaneously. Swedish wheels combine aspects of both Mecanum and omni wheels, providing enhanced maneuverability and precise control in robotic platforms. These wheel types are integral to achieving high degrees of freedom in robotic mobility, essential for applications requiring agile and versatile movement.

Applications of Omnidirectional Wheels in Mobile Robots

Omnidirectional wheels enable mobile robots to move seamlessly in any direction without changing orientation, significantly enhancing maneuverability in confined spaces such as warehouses and hospitals. These wheels are commonly utilized in automated guided vehicles (AGVs) and service robots to perform complex tasks requiring precise navigation and positioning. The integration of omnidirectional wheels facilitates efficient multi-directional movement, improving operational productivity and flexibility in dynamic environments.

Omnidirectional Wheel Robots in Industrial Automation

Omnidirectional wheel robots in industrial automation enhance maneuverability by enabling movement in any direction without changing orientation, significantly improving efficiency in tight or complex factory layouts. These robots utilize mecanum or omni wheels, which consist of rollers mounted at specific angles, allowing seamless lateral, diagonal, and rotational movement. Implementing omnidirectional wheel technology reduces cycle times in material handling and assembly lines, optimizing production workflows and supporting flexible manufacturing systems.

Omnidirectional Drives in Service Robotics

Omnidirectional wheels, such as Mecanum and omni wheels, enable service robots to move seamlessly in any direction by allowing independent control of each wheel's speed and rotation. These omnidirectional drives enhance maneuverability in constrained environments like hospitals and hotels, improving task efficiency and navigation precision. Integrating these wheels in robotic platforms supports advanced service functions including autonomous delivery, cleaning, and human interaction.

Advancements in Robotic Mobility with Omnidirectional Wheels

Omnidirectional wheels, featuring multiple rollers arranged around their circumference, enable robots to move in any direction without changing orientation, significantly enhancing maneuverability in tight spaces. Recent advancements include the integration of high-torque motors and precision encoders, improving control accuracy and load-bearing capacity for industrial and service robots. These improvements facilitate complex navigation tasks in dynamic environments, making omnidirectional wheels a key innovation in modern robotic mobility systems.

Case Study: Mecanum Wheels in Autonomous Robots

Mecanum wheels enable omnidirectional mobility in autonomous robots by allowing smooth lateral, diagonal, and rotational movements without changing the robot's orientation. These wheels consist of a series of rollers mounted at a 45-degree angle, providing high maneuverability in confined spaces, commonly used in warehouse automation and service robots. Case studies show Mecanum-wheel-equipped robots improve operational efficiency by navigating complex environments with precision and minimal mechanical complexity.

Challenges and Limitations of Omnidirectional Wheel Integration

Omnidirectional wheels in robotics enable advanced maneuverability but face challenges such as increased mechanical complexity and higher maintenance requirements due to multiple rollers. Integration often leads to stability issues on uneven terrain, limiting their effectiveness in outdoor applications. Power consumption can also rise significantly, impacting battery life and operational duration.

Future Trends in Omnidirectional Wheel Robotics

Future trends in omnidirectional wheel robotics emphasize enhanced maneuverability and improved efficiency in autonomous navigation across complex environments. Innovations include the integration of advanced materials for lightweight, durable wheels and AI-driven control systems for precise motion planning. Research focuses on scalable designs applicable to drones, delivery robots, and automated warehouses, expanding usability in dynamic, crowded spaces.

example of omnidirectional wheel in robotics Infographic

samplerz.com

samplerz.com