A bogie in railway systems is a crucial component that supports and guides train wheels, allowing for smoother and safer movement. Typically, a bogie consists of a frame, suspension, axles, and wheels, designed to distribute the weight and absorb shocks from the tracks. Modern passenger and freight trains use advanced bogie designs to enhance stability, reduce noise, and improve overall ride comfort. Various types of bogies include two-axle and three-axle configurations, each tailored to different load capacities and speed requirements. Innovations have introduced self-steering and active suspension bogies, which adapt to track curves and irregularities for optimal performance. Rail companies deploy these bogies across multiple train models to ensure efficiency, safety, and longevity in railway operations.

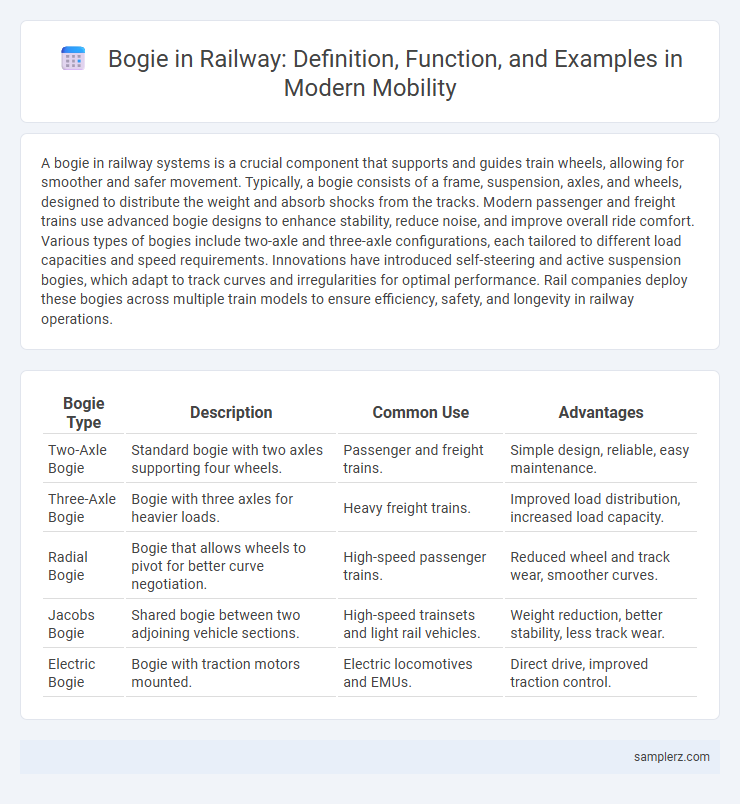

Table of Comparison

| Bogie Type | Description | Common Use | Advantages |

|---|---|---|---|

| Two-Axle Bogie | Standard bogie with two axles supporting four wheels. | Passenger and freight trains. | Simple design, reliable, easy maintenance. |

| Three-Axle Bogie | Bogie with three axles for heavier loads. | Heavy freight trains. | Improved load distribution, increased load capacity. |

| Radial Bogie | Bogie that allows wheels to pivot for better curve negotiation. | High-speed passenger trains. | Reduced wheel and track wear, smoother curves. |

| Jacobs Bogie | Shared bogie between two adjoining vehicle sections. | High-speed trainsets and light rail vehicles. | Weight reduction, better stability, less track wear. |

| Electric Bogie | Bogie with traction motors mounted. | Electric locomotives and EMUs. | Direct drive, improved traction control. |

Understanding Bogies: Definition and Function in Rail Mobility

A bogie is a chassis or framework that carries a set of wheels, allowing railway vehicles to navigate tracks smoothly and maintain stability. It distributes the load of the railcar, absorbs shocks, and enables better steering through curves by pivoting beneath the vehicle. Understanding bogies is essential for optimizing rail mobility, as their design directly impacts ride comfort, safety, and overall train performance.

Key Components of a Railway Bogie

A railway bogie consists of key components including the wheelsets, suspension system, and the bogie frame, which collectively ensure stability and smooth movement on tracks. The suspension system typically integrates primary and secondary springs to absorb shocks and vibrations, enhancing passenger comfort and cargo safety. Wheelsets, comprising axles and wheels, are critical for weight distribution and directional guidance, allowing the bogie to navigate curves efficiently.

Historical Evolution of Railway Bogies

Railway bogies have evolved significantly since their inception in the early 19th century, transitioning from simple wooden frames to advanced steel structures equipped with suspension systems for enhanced stability and ride comfort. The introduction of the three-piece bogie in the late 1800s marked a pivotal innovation, improving weight distribution and track adherence. Modern bogies incorporate air suspension, anti-slip technology, and modular designs, reflecting continuous advancements driven by increasing train speeds and passenger comfort demands.

Modern Bogie Designs and Innovations

Modern bogie designs in railway systems incorporate advanced suspension technologies and lightweight materials to enhance ride comfort and reduce track wear. Innovations such as active suspension, modular construction, and noise reduction features improve stability and energy efficiency. These developments contribute to higher speeds, better passenger safety, and lower maintenance costs.

Examples of Bogie Types Used Worldwide

Bogie types used worldwide in railway systems include the bolster bogie, which features a central bolster beam supporting the car body, enhancing stability on curves. The radial bogie allows wheels to align with the track curve, reducing wheel and rail wear, commonly used in high-speed trains in Japan and Europe. Additionally, the three-axle bogie improves load distribution for heavy freight trains, widely adopted in North American and Australian rail networks.

The Role of Bogies in High-Speed Trains

Bogie systems in high-speed trains play a critical role in enhancing stability and passenger comfort by reducing vibrations and noise at velocities exceeding 300 km/h. These specialized bogies incorporate advanced suspension technologies and aerodynamic designs to ensure smooth cornering and optimal track contact. Efficient bogie design directly impacts safety, energy efficiency, and maintenance frequency in modern high-speed rail networks.

Common Materials Used in Bogie Construction

Bogie construction in railways primarily utilizes high-strength steel alloys such as manganese steel and carbon steel for their durability and resistance to wear and fatigue. Cast iron components are often integrated for their excellent vibration damping properties, while aluminum alloys are occasionally used to reduce weight in high-speed trains. Rubber and composite materials are incorporated in suspension systems to enhance shock absorption and passenger comfort.

Maintenance and Safety Considerations for Railway Bogies

Railway bogie maintenance involves regular inspection of wheelsets, suspension components, and braking systems to ensure optimal performance and safety. Monitoring wear and tear through ultrasonic testing and vibration analysis helps prevent mechanical failures and derailments. Implementing predictive maintenance strategies reduces downtime and enhances operational reliability on rail networks.

Impact of Advanced Bogie Technology on Passenger Comfort

Advanced bogie technology, such as active suspension systems and vibration damping materials, significantly enhances passenger comfort by reducing noise, vibrations, and lateral forces during travel. Innovations like self-steering bogies improve stability and smoothness, minimizing track wear and providing a quieter ride. These improvements contribute to safer, more comfortable journeys and increased operational efficiency in modern rail transport.

Future Trends in Bogie Design and Application

Future trends in bogie design emphasize lightweight materials such as carbon fiber composites and advanced alloys to improve energy efficiency and reduce maintenance costs. Integration of smart sensors and IoT technology enables real-time monitoring of bogie components for predictive maintenance, enhancing safety and reliability. Autonomous adjustment mechanisms are being developed to optimize suspension performance dynamically, improving ride comfort and track interaction under varying operational conditions.

example of bogie in railway Infographic

samplerz.com

samplerz.com