A mezzanine in a warehouse is an intermediate floor structure installed between the main floors to increase usable space without expanding the building footprint. This elevated platform is typically used for storage, office areas, or equipment placement, optimizing vertical space in industrial facilities. Mezzanines are constructed from steel or aluminum with open-grid decking to maintain visibility and airflow. In real estate, mezzanines enhance warehouse functionality by providing additional square footage that supports inventory management and operational efficiency. They can be customized to accommodate heavy loads and are often designed in compliance with local building codes and safety regulations. Property investors value mezzanines for their ability to boost rental income potential by maximizing leasable space within existing structures.

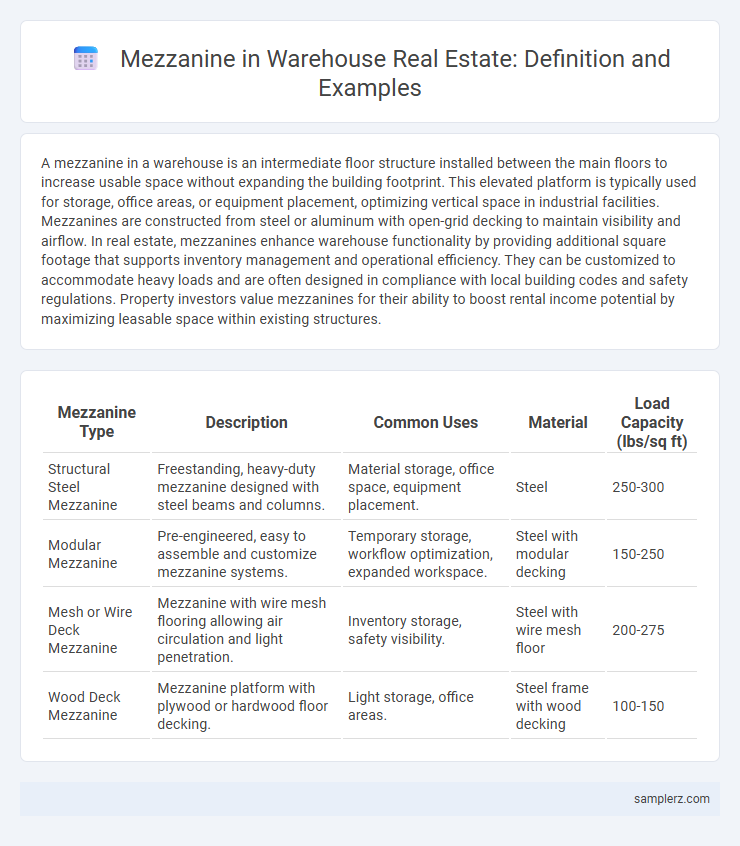

Table of Comparison

| Mezzanine Type | Description | Common Uses | Material | Load Capacity (lbs/sq ft) |

|---|---|---|---|---|

| Structural Steel Mezzanine | Freestanding, heavy-duty mezzanine designed with steel beams and columns. | Material storage, office space, equipment placement. | Steel | 250-300 |

| Modular Mezzanine | Pre-engineered, easy to assemble and customize mezzanine systems. | Temporary storage, workflow optimization, expanded workspace. | Steel with modular decking | 150-250 |

| Mesh or Wire Deck Mezzanine | Mezzanine with wire mesh flooring allowing air circulation and light penetration. | Inventory storage, safety visibility. | Steel with wire mesh floor | 200-275 |

| Wood Deck Mezzanine | Mezzanine platform with plywood or hardwood floor decking. | Light storage, office areas. | Steel frame with wood decking | 100-150 |

Understanding Warehouse Mezzanines: Key Concepts

Warehouse mezzanines maximize vertical space by creating an intermediate floor within existing structures, often constructed from steel for durability and flexibility. These elevated platforms enhance storage capacity, streamline inventory organization, and improve operational workflows without requiring facility expansion. Key concepts include load-bearing capacity, compliance with safety regulations, and integration with warehouse management systems to optimize space utilization and efficiency.

Benefits of Adding Mezzanines to Warehouse Spaces

Adding mezzanines to warehouse spaces significantly increases usable square footage without expanding the building footprint, optimizing vertical space for storage and operations. Mezzanines improve workflow efficiency by enabling better organization and easy access to inventory, reducing retrieval time and labor costs. Enhanced structural flexibility allows warehouses to adapt quickly to changing storage needs, making mezzanines a cost-effective solution for maximizing capacity and operational productivity.

Common Uses of Mezzanines in Warehouses

Mezzanines in warehouses are commonly used to maximize vertical space by creating additional storage areas, improving inventory organization, and facilitating better workflow. These intermediate floors support heavy-duty shelving, enable efficient sorting and packing operations, and often house office spaces or equipment platforms without expanding the building footprint. Their modular design allows for easy customization and scalability, making them an essential solution for optimizing warehouse functionality and operational efficiency.

Industrial Storage Optimization Through Mezzanines

Mezzanine floors in warehouses maximize vertical space, increasing storage capacity without expanding the building footprint. Industrial storage optimization through mezzanines enhances inventory management by creating additional shelving and operational areas above ground level. This method reduces clutter, improves workflow efficiency, and supports scalable growth in warehouse facilities.

Design Ideas: Modern Warehouse Mezzanine Examples

Modern warehouse mezzanine designs utilize sleek steel framing combined with tempered glass railings to enhance natural light and visibility, optimizing both aesthetics and functionality. Modular mezzanine platforms with integrated LED lighting and automated storage systems create efficient use of vertical space while supporting heavy loads. Innovative layouts incorporate open-plan office pods and break areas above storage zones, promoting seamless workflow and maximizing floor-to-ceiling height utility.

Cost Considerations for Warehouse Mezzanine Installations

Warehouse mezzanine installations reduce the need for new building acquisitions by maximizing vertical space, significantly lowering overall operational costs. Material selection, load capacity requirements, and local building codes directly influence installation expenses, with steel mezzanines often providing a cost-effective balance of durability and affordability. Factoring in ongoing maintenance costs alongside initial investment helps optimize budget planning for long-term warehouse mezzanine use.

Safety Standards for Warehouse Mezzanine Structures

Warehouse mezzanine structures must comply with OSHA standards 1910.29 for fall protection to ensure worker safety during loading and unloading operations. Steel mezzanines should be designed to support live loads of at least 125 pounds per square foot, as recommended by the International Building Code (IBC) and American Institute of Steel Construction (AISC). Proper guardrails, safety gates, and load capacity signage are essential to prevent accidents and maintain compliance with National Fire Protection Association (NFPA) regulations.

Case Studies: Mezzanine Projects in Real Warehouses

Mezzanine installations in warehouses demonstrate increased storage capacity and operational efficiency, as seen in Case Studies such as the XYZ Logistics Center, where a steel mezzanine added 30% additional floor space without expanding the building footprint. Another example is the ABC Distribution Hub, which integrated modular mezzanines to optimize inventory management and streamline workflow. These projects highlight how mezzanine systems serve as cost-effective solutions to maximize vertical space utilization in real industrial environments.

Choosing the Right Mezzanine System for Your Warehouse

Selecting the right mezzanine system for your warehouse involves analyzing load capacity, available ceiling height, and intended use such as storage or office space. Steel frame mezzanines offer durability and flexibility, supporting heavy inventory and allowing customization to maximize floor area. Prioritize modular designs that facilitate future expansion and integrate seamlessly with existing warehouse infrastructure for optimal workflow efficiency.

Maximizing ROI with Warehouse Mezzanine Solutions

Warehouse mezzanine solutions significantly maximize ROI by adding valuable square footage without the need for costly facility expansions. Incorporating durable steel mezzanines enables businesses to optimize vertical space for storage, increasing inventory capacity by up to 50%. Efficiently designed mezzanines improve workflow and reduce operational downtime, directly impacting profitability and asset utilization.

example of mezzanine in warehouse Infographic

samplerz.com

samplerz.com