Gyroscooters play a crucial role in optimizing warehouse mobility by enabling workers to move goods efficiently across large spaces. These self-balancing devices incorporate gyroscopic sensors that maintain stability, allowing operators to navigate tight aisles and uneven surfaces with ease. Warehouses equipped with gyroscooters experience increased productivity as inventory handling becomes faster and less physically demanding. Data from logistics studies indicate that gyroscooters can reduce time spent on internal transportation by up to 30%, directly impacting operational costs. The integration of gyroscooters also contributes to ergonomic benefits, minimizing strain and injury risks among warehouse employees. This technological advancement supports modern warehouse management systems aiming for smarter, faster, and safer material movement.

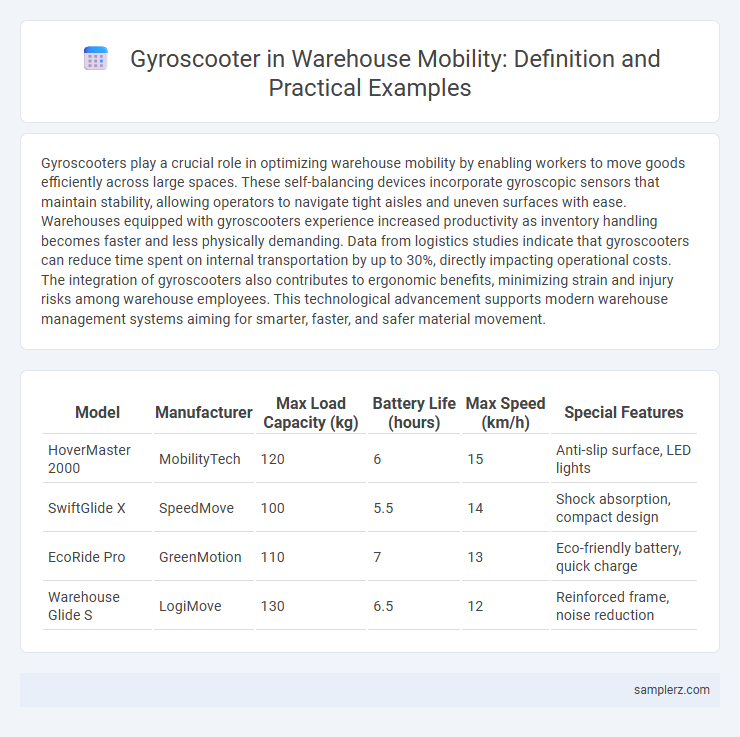

Table of Comparison

| Model | Manufacturer | Max Load Capacity (kg) | Battery Life (hours) | Max Speed (km/h) | Special Features |

|---|---|---|---|---|---|

| HoverMaster 2000 | MobilityTech | 120 | 6 | 15 | Anti-slip surface, LED lights |

| SwiftGlide X | SpeedMove | 100 | 5.5 | 14 | Shock absorption, compact design |

| EcoRide Pro | GreenMotion | 110 | 7 | 13 | Eco-friendly battery, quick charge |

| Warehouse Glide S | LogiMove | 130 | 6.5 | 12 | Reinforced frame, noise reduction |

Enhancing Warehouse Mobility with Gyroscooters

Gyroscooters significantly enhance warehouse mobility by enabling workers to move quickly and efficiently across large storage areas, reducing walking time and increasing productivity. Their compact design allows easy navigation through narrow aisles, minimizing physical strain and improving operational safety. Integration of gyroscooters with warehouse management systems further optimizes task allocation and streamlines inventory handling processes.

Key Features of Gyroscooters for Warehouse Operations

Gyroscooters in warehouse operations offer enhanced maneuverability with their compact design and precise balance control, enabling workers to navigate tight aisles efficiently. Equipped with robust battery life and shock-absorbing wheels, these devices support prolonged usage on uneven warehouse floors, increasing productivity. Integrated safety features such as speed limiters and automatic braking systems ensure secure handling in busy environments.

Safety Benefits of Gyroscooters in Warehouses

Gyroscooters enhance safety in warehouses by reducing worker fatigue, which decreases the likelihood of accidents caused by tiredness or loss of focus. Their compact design enables operators to navigate tight spaces quickly and smoothly, minimizing collision risks with inventory or personnel. Equipped with stable balancing technology, gyroscooters offer improved control and reduce fall-related injuries compared to manual walking or traditional carts.

Case Studies: Gyroscooters in Logistics Facilities

Gyroscooters have revolutionized mobility in logistics facilities by significantly enhancing worker efficiency and reducing fatigue during lengthy warehouse shifts. Case studies demonstrate that implementing gyroscooters in large-scale warehouses, such as Amazon fulfillment centers, resulted in a 25% increase in task completion speed and a 15% reduction in workplace injuries. The compact design and intuitive controls of gyroscooters enable seamless navigation through narrow aisles, optimizing the flow of goods and improving overall operational productivity.

Comparing Gyroscooters to Traditional Warehouse Vehicles

Gyroscooters offer enhanced maneuverability and reduced fatigue compared to traditional warehouse vehicles like forklifts and pallet jacks. Their compact design allows operators to navigate tight aisles and crowded spaces efficiently, improving overall productivity and safety. Unlike conventional vehicles, gyroscooters require minimal training and maintenance, making them a cost-effective mobility solution in modern warehouse environments.

Implementing Gyroscooters in Large-Scale Warehouses

Implementing gyroscooters in large-scale warehouses enhances worker mobility by significantly reducing travel time across vast storage areas. These self-balancing personal transporters increase operational efficiency and reduce physical strain, enabling faster order picking and inventory management. Integration with warehouse management systems optimizes routing and safety protocols, maximizing productivity in complex logistics environments.

Reducing Worker Fatigue with Gyroscooters

Gyroscooters in warehouses significantly reduce worker fatigue by minimizing physical exertion during long hours of material handling. These electric mobility devices allow employees to move swiftly and efficiently across extensive warehouse floors, decreasing strain on legs and joints. Enhanced mobility from gyroscooters leads to increased productivity and improved worker well-being in demanding logistics environments.

Training Staff for Gyroscooter Use in Warehouses

Training staff for gyroscooter use in warehouses significantly improves operational efficiency and safety by reducing accidents and enhancing maneuverability through tight aisles. Structured programs covering balance control, speed regulation, and hazard awareness ensure employees can confidently navigate the warehouse environment. Regular refresher courses and hands-on practice promote long-term proficiency and decrease downtime caused by misuse or accidents.

Gyroscooter Maintenance and Longevity in Industrial Settings

Regular gyroscooter maintenance in warehouses ensures optimal performance and extends device longevity by preventing wear on critical components such as motors, batteries, and wheels. Implementing scheduled inspections and timely battery replacements minimizes downtime and maintains safety standards in industrial mobility operations. Proper lubrication and calibration of gyroscooter sensors contribute to accurate navigation and stable handling, reducing the risk of operational failures in warehouse environments.

Future Trends: Next-Gen Mobility Solutions in Warehousing

Gyroscooters in warehousing represent a significant shift towards next-generation mobility solutions by enhancing worker efficiency and reducing fatigue during long shifts. These electric self-balancing devices enable rapid, agile movement across large storage areas, improving order picking and inventory management processes. Integration with IoT and AI technologies in future models promises real-time navigation optimization and seamless connectivity within smart warehouses.

example of gyroscooter in warehouse Infographic

samplerz.com

samplerz.com