Cross-docking in retail fulfillment centers involves the direct transfer of products from inbound trucks to outbound trucks, minimizing storage time. For example, a fulfillment center receiving electronics from multiple suppliers immediately sorts and consolidates items destined for regional stores. This process reduces inventory holding costs and speeds up order delivery. Retail giant Walmart employs cross-docking extensively in its fulfillment centers to optimize supply chain efficiency. Products such as fresh produce and household goods are quickly routed through the dock, bypassing traditional warehousing. Data from Walmart shows that cross-docking can reduce delivery times by up to 50%, enhancing customer satisfaction and streamlining inventory management.

Table of Comparison

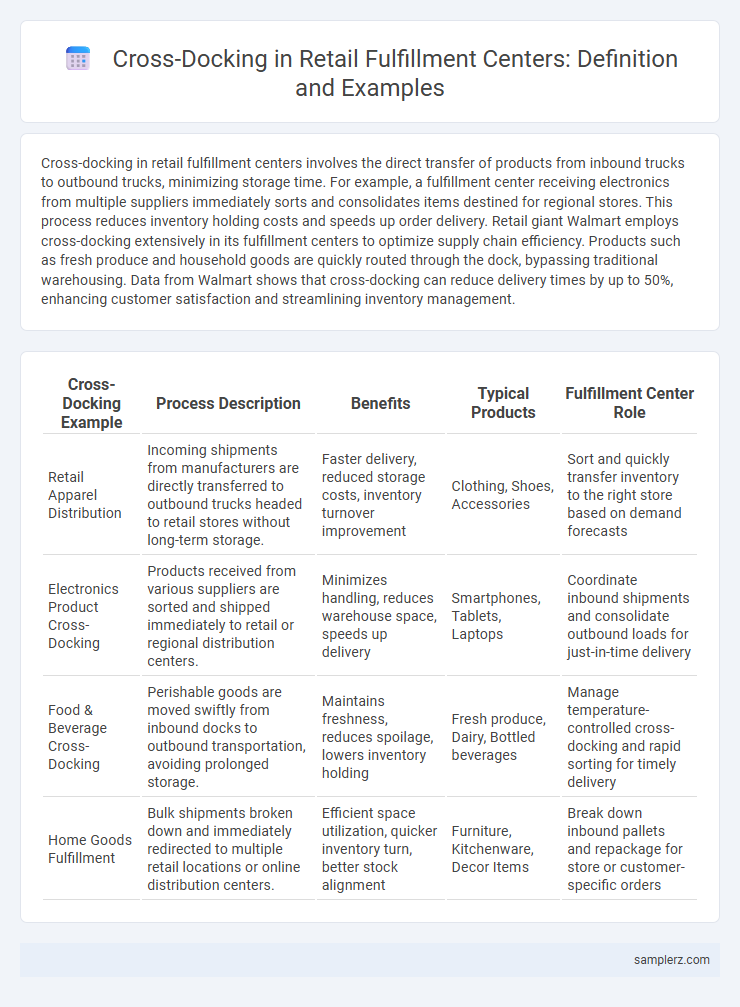

| Cross-Docking Example | Process Description | Benefits | Typical Products | Fulfillment Center Role |

|---|---|---|---|---|

| Retail Apparel Distribution | Incoming shipments from manufacturers are directly transferred to outbound trucks headed to retail stores without long-term storage. | Faster delivery, reduced storage costs, inventory turnover improvement | Clothing, Shoes, Accessories | Sort and quickly transfer inventory to the right store based on demand forecasts |

| Electronics Product Cross-Docking | Products received from various suppliers are sorted and shipped immediately to retail or regional distribution centers. | Minimizes handling, reduces warehouse space, speeds up delivery | Smartphones, Tablets, Laptops | Coordinate inbound shipments and consolidate outbound loads for just-in-time delivery |

| Food & Beverage Cross-Docking | Perishable goods are moved swiftly from inbound docks to outbound transportation, avoiding prolonged storage. | Maintains freshness, reduces spoilage, lowers inventory holding | Fresh produce, Dairy, Bottled beverages | Manage temperature-controlled cross-docking and rapid sorting for timely delivery |

| Home Goods Fulfillment | Bulk shipments broken down and immediately redirected to multiple retail locations or online distribution centers. | Efficient space utilization, quicker inventory turn, better stock alignment | Furniture, Kitchenware, Decor Items | Break down inbound pallets and repackage for store or customer-specific orders |

Overview of Cross-Docking in Retail Fulfillment Centers

Cross-docking in retail fulfillment centers involves the direct transfer of products from inbound to outbound transportation with minimal storage time, optimizing inventory flow and reducing handling costs. This process is particularly effective for high-demand items, perishable goods, and time-sensitive shipments, enhancing delivery speed and efficiency. Implementing cross-docking systems improves supply chain responsiveness and decreases warehouse operational expenses, driving better customer satisfaction in retail environments.

Key Benefits of Cross-Docking for Retailers

Cross-docking in fulfillment centers minimizes inventory holding costs by directly transferring products from inbound to outbound shipments, accelerating order fulfillment and reducing storage needs. This process enhances supply chain efficiency, leading to faster delivery times and improved customer satisfaction. Retailers benefit from reduced handling errors and lower transportation expenses, supporting leaner operations and increased competitiveness.

Types of Cross-Docking Strategies in Retail

In retail fulfillment centers, cross-docking strategies include pre-distribution cross-docking, where products are sorted and distributed immediately upon arrival without storage, and flow-through cross-docking, which involves minimal handling by moving products directly from inbound to outbound transportation. Hybrid cross-docking combines elements of both strategies, allowing selective storage of certain products while others are dispatched instantly. These methods optimize inventory turnover rates, reduce storage costs, and increase supply chain efficiency.

Real-World Cross-Docking Example: Major Retail Chain

A major retail chain employs cross-docking at its fulfillment center by receiving products directly from suppliers and immediately sorting them for outbound shipment to stores, minimizing storage time and reducing handling costs. This process enables the retailer to accelerate inventory turnover and improve order accuracy, ensuring shelves are stocked quickly with high-demand items. Efficient cross-docking streamlines the supply chain, boosts customer satisfaction, and lowers operational expenses across the retail network.

Step-by-Step Process of Cross-Docking in Fulfillment Centers

Cross-docking in fulfillment centers begins with receiving inbound goods directly from suppliers, where items are quickly sorted based on destination. Next, products are immediately transferred to outbound docks without long-term storage, optimizing inventory flow. Finally, these items are loaded onto delivery vehicles for rapid distribution to retail stores, minimizing handling time and reducing storage costs.

Technology Solutions Enabling Cross-Docking Efficiency

Advanced warehouse management systems (WMS) with real-time inventory tracking enable seamless cross-docking by automatically matching incoming shipments with outbound orders in retail fulfillment centers. RFID technology streamlines product identification and sorting, reducing handling time and minimizing errors during the transfer process. Automated conveyor systems integrated with AI-driven route optimization further enhance operational speed and accuracy, significantly boosting cross-docking efficiency in retail supply chains.

Challenges and Risks in Retail Cross-Docking

Cross-docking in retail fulfillment centers faces challenges such as inventory inaccuracies, which can disrupt the seamless transfer of goods and delay order fulfillment. Risks include increased dependency on real-time data systems that, if malfunctioning, cause bottlenecks and stockouts. Effective coordination between suppliers and logistics teams is crucial to mitigate these risks and maintain efficient inventory flow.

Role of Third-Party Logistics in Cross-Docking Operations

Third-party logistics (3PL) providers play a critical role in cross-docking operations by managing the seamless transfer of goods from inbound to outbound transportation without long-term storage. These specialists optimize inventory flow, reduce handling times, and enhance delivery speed through advanced warehouse management systems and real-time tracking. Leveraging 3PL expertise improves supply chain efficiency, lowers operational costs, and ensures timely fulfillment in retail distribution centers.

Cross-Docking Success Stories in E-commerce Fulfillment

A major e-commerce retailer implemented cross-docking at its fulfillment center, reducing delivery times by 30% and cutting inventory holding costs significantly. By directly transferring products from inbound to outbound shipments, the retailer enhanced order accuracy and improved customer satisfaction rates. This efficient approach to cross-docking optimized warehouse space utilization and streamlined supply chain operations, driving rapid order fulfillment during peak sales seasons.

Future Trends of Cross-Docking in the Retail Industry

Future trends in cross-docking within retail fulfillment centers emphasize advanced automation and real-time data integration to enhance inventory accuracy and reduce delivery times. Leveraging AI-powered analytics enables predictive demand forecasting, minimizing storage costs and optimizing shipment routing. Embracing IoT technology further streamlines cross-docking operations by providing end-to-end visibility and improving supply chain responsiveness.

example of cross-docking in fulfillment center Infographic

samplerz.com

samplerz.com