Kaizen, a Japanese term meaning "continuous improvement," plays a significant role in enhancing productivity within organizations. This approach emphasizes small, incremental changes that collectively lead to substantial improvements in efficiency and quality. For example, a manufacturing company might implement kaizen by regularly analyzing workflows and encouraging employees to suggest minor adjustments that reduce waste and streamline production processes. In practice, kaizen involves data-driven decision-making, where performance metrics are monitored to identify areas needing improvement. Teams use this information to implement targeted changes, such as reorganizing workstations or updating machinery maintenance schedules. Over time, these continual refinements help increase output, reduce downtime, and foster a culture of proactive problem-solving.

Table of Comparison

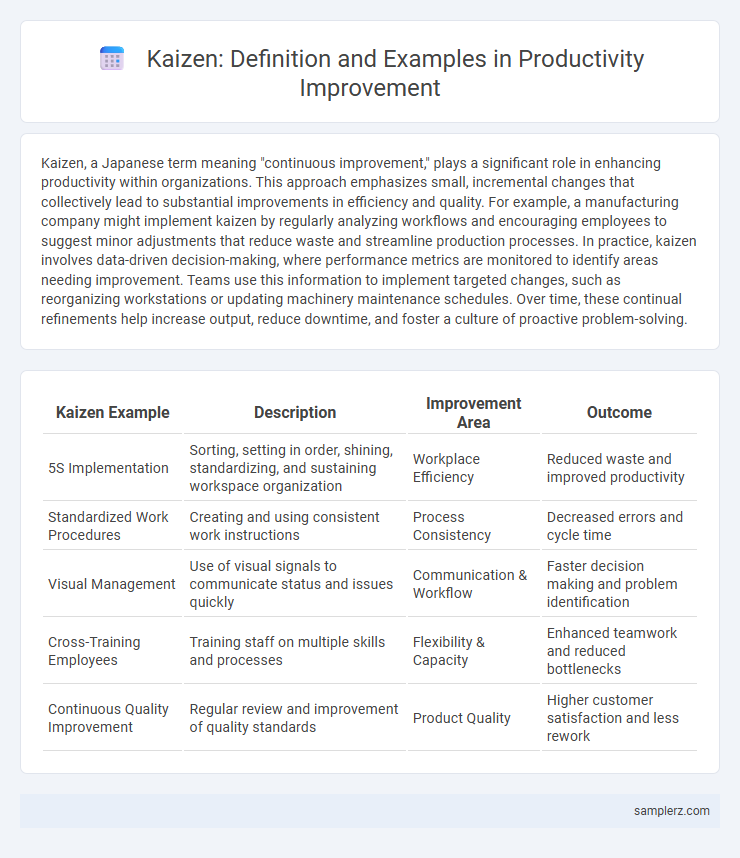

| Kaizen Example | Description | Improvement Area | Outcome |

|---|---|---|---|

| 5S Implementation | Sorting, setting in order, shining, standardizing, and sustaining workspace organization | Workplace Efficiency | Reduced waste and improved productivity |

| Standardized Work Procedures | Creating and using consistent work instructions | Process Consistency | Decreased errors and cycle time |

| Visual Management | Use of visual signals to communicate status and issues quickly | Communication & Workflow | Faster decision making and problem identification |

| Cross-Training Employees | Training staff on multiple skills and processes | Flexibility & Capacity | Enhanced teamwork and reduced bottlenecks |

| Continuous Quality Improvement | Regular review and improvement of quality standards | Product Quality | Higher customer satisfaction and less rework |

Daily Stand-Up Meetings: A Kaizen Approach

Daily stand-up meetings exemplify Kaizen's continuous improvement by promoting team alignment, quick problem-solving, and transparency. These brief gatherings encourage daily feedback loops that identify inefficiencies and foster incremental progress. Implementing Kaizen in daily stand-ups leads to enhanced productivity through consistent, small-scale adjustments.

Streamlining Workflow with 5S Methodology

The 5S methodology--Sort, Set in order, Shine, Standardize, Sustain--streamlines workflow by eliminating waste and organizing the workspace for maximum efficiency. Implementing 5S in manufacturing plants has reduced search times by up to 30%, improving overall productivity and safety. Continuous adherence to 5S principles fosters a culture of discipline and constant improvement aligned with Kaizen philosophy.

Small-Scale Process Improvements in Manufacturing

Kaizen in manufacturing emphasizes continuous small-scale process improvements that enhance productivity and reduce waste. Examples include rearranging workstations for smoother workflows, implementing standardized work procedures, and using visual management tools to identify inefficiencies quickly. These incremental changes contribute to sustained operational efficiency and cost savings.

Reducing Waste with Continuous Feedback Loops

Kaizen improves productivity by systematically reducing waste through continuous feedback loops, enabling iterative process refinement and enhanced resource utilization. Implementing regular team reviews and immediate adjustments minimizes inefficiencies and accelerates problem-solving. This approach drives sustainable performance gains by fostering a culture of ongoing evaluation and incremental improvement.

Employee Suggestions: Fueling Incremental Change

Employee suggestions play a pivotal role in Kaizen implementation, fostering continuous incremental change within organizations. By encouraging workers to identify inefficiencies and propose practical improvements, companies harness frontline insights to enhance productivity and reduce waste. This participatory approach aligns with Kaizen's core principle of sustained, small-scale enhancements driven by those directly involved in daily operations.

Standardizing Tasks for Consistent Results

Kaizen emphasizes standardizing tasks to achieve consistent results by eliminating variability and streamlining processes. Documenting best practices and creating clear work instructions help teams maintain quality and reduce errors. Continuous feedback loops ensure ongoing refinement and sustained productivity improvements across the organization.

Visual Management Tools in Office Settings

Kaizen principles boost productivity by implementing Visual Management Tools such as Kanban boards and color-coded charts in office settings. These tools streamline workflow, promote transparency, and enable real-time tracking of tasks and progress. Utilizing these visual aids enhances team collaboration and reduces inefficiencies in daily operations.

Cross-Department Collaboration for Problem Solving

Kaizen promotes continuous improvement by fostering cross-department collaboration to identify and solve problems efficiently. Teams from different departments share insights and expertise, breaking down silos to enhance workflow and innovation. This collaborative approach accelerates issue resolution and drives sustained productivity gains across the organization.

Quick Wins: Rapid Implementation of Small Ideas

Kaizen drives productivity improvement by emphasizing Quick Wins, which involve the rapid implementation of small, incremental ideas that enhance processes and eliminate waste. These swift changes, such as rearranging workstations or adjusting workflow steps, lead to immediate benefits like reduced cycle times and increased employee engagement. By consistently applying Quick Wins, organizations sustain momentum toward larger, long-term operational excellence goals.

Measuring Success: Tracking Kaizen Improvements

Tracking Kaizen improvements involves using key performance indicators (KPIs) like cycle time reduction, defect rate decrease, and employee productivity metrics to measure success. Implementing regular data collection through visual management tools such as Kanban boards and scorecards ensures continuous monitoring and adjustment of processes. These measurement strategies enable organizations to quantify the impact of incremental changes and promote sustainable productivity growth.

example of kaizen in improvement Infographic

samplerz.com

samplerz.com