An autorack is a specialized railcar designed to transport vehicles efficiently across long distances. These railcars feature multiple levels and enclosed sides to protect automobiles from weather and damage during transit. Rail companies often use autoracks in freight trains to move large volumes of cars between manufacturing plants and distribution centers. Autoracks play a crucial role in the automotive supply chain by enabling bulk shipment of vehicles by rail instead of road. The design maximizes capacity, allowing dozens of cars to be stacked vertically while securely fastened. In the context of mobility, autoracks support mass vehicle movement that maintains cost-effectiveness and reduces highway congestion.

Table of Comparison

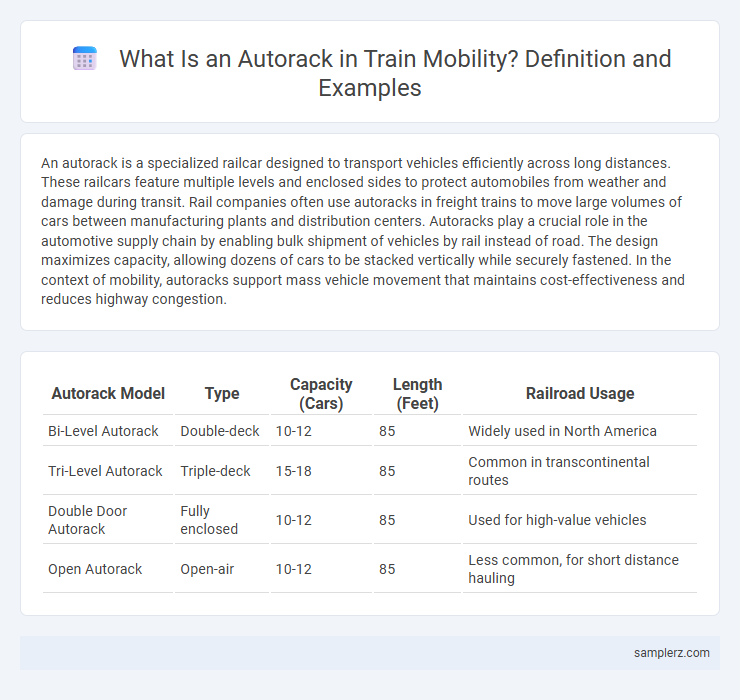

| Autorack Model | Type | Capacity (Cars) | Length (Feet) | Railroad Usage |

|---|---|---|---|---|

| Bi-Level Autorack | Double-deck | 10-12 | 85 | Widely used in North America |

| Tri-Level Autorack | Triple-deck | 15-18 | 85 | Common in transcontinental routes |

| Double Door Autorack | Fully enclosed | 10-12 | 85 | Used for high-value vehicles |

| Open Autorack | Open-air | 10-12 | 85 | Less common, for short distance hauling |

Introduction to Autoracks in Rail Transportation

Autoracks in rail transportation are specialized railcars designed specifically for the safe and efficient transport of automobiles. These multi-level freight cars maximize cargo capacity while protecting vehicles from weather and damage during transit. Their widespread use in the automotive supply chain enhances logistics efficiency by enabling large-scale, cost-effective movement of cars between manufacturing plants and distribution centers.

Evolution of Autorack Design in Modern Railways

Modern autorack designs in railways have evolved to incorporate multi-level, bi-level, and tri-level configurations, significantly increasing vehicle transport capacity per train. Innovations include enhanced ventilation systems, improved loading mechanisms, and the use of lightweight, corrosion-resistant materials to optimize fuel efficiency and reduce maintenance costs. Advanced safety features such as reinforced side panels and secure locking mechanisms protect vehicles during transit, reflecting the ongoing commitment to efficiency and reliability in autorack evolution.

Key Features of Autorack Train Cars

Autorack train cars feature multi-level decks designed to maximize vehicle capacity while ensuring secure transportation with heavy-duty restraints. These railcars incorporate advanced ventilation systems to prevent moisture buildup and reduce corrosion during transit. Robust construction with impact-resistant materials enhances durability, accommodating various vehicle sizes efficiently across long-distance freight routes.

Types of Autoracks Used in Freight Mobility

Autoracks in freight mobility primarily include bi-level, tri-level, and multi-level configurations designed to maximize vehicle transportation efficiency. Bi-level autoracks accommodate larger vehicles like SUVs, tri-level autoracks are optimized for standard cars, and multi-level autoracks offer enhanced capacity for mixed vehicle types. These types enable rail networks to transport a high volume of automobiles securely and cost-effectively across long distances.

Global Use Cases: Autorack Trains Around the World

Autorack trains are extensively used in regions including North America, Europe, and Asia for efficient automotive transport, leveraging multi-level railcars to maximize vehicle capacity and protect against damage. In the United States, companies like Union Pacific and CSX operate specialized autorack services connecting manufacturing hubs with distribution centers, while European operators utilize autoracks designed to navigate dense urban networks and cross-border routes. Japan's Shinkansen network integrates autorack technology for fast, reliable car shipment alongside passenger services, demonstrating global adaptation to diverse logistical and infrastructure requirements.

Efficiency Benefits: How Autoracks Improve Vehicle Transport

Autoracks significantly enhance vehicle transport efficiency by maximizing train cargo capacity, allowing for the secure stacking of multiple cars across multiple levels. Their design reduces the need for separate shipments, cutting down transit times and lowering fuel consumption per vehicle transported. The integration of autoracks into rail logistics streamlines loading and unloading processes, resulting in faster turnaround times and reduced operational costs.

Case Study: Autorack Operations in North America

Autorack operations in North America utilize multi-level railcars designed to transport vehicles efficiently across extensive rail networks. These specialized railcars maximize cargo density while ensuring vehicle protection from weather and damage during transit. Key operators like Canadian National and Union Pacific leverage autoracks to support automotive manufacturers and dealerships in delivering vehicles continent-wide.

Safety Innovations in Autorack Train Systems

Modern autorack train systems integrate advanced safety innovations such as reinforced sidewalls, fire-resistant materials, and automated door locking mechanisms to protect vehicles during transit. Impact detection sensors and real-time monitoring systems enhance accident prevention by alerting operators to potential hazards. These technologies reduce damage risk, improve cargo security, and elevate overall rail transport safety standards.

Environmental Impact of Autorack Mobility Solutions

Autorack trains significantly reduce carbon emissions by transporting large volumes of vehicles efficiently over long distances, lowering the reliance on multiple truck shipments. Utilizing specialized railcars with stacked vehicle compartments maximizes load capacity, leading to decreased fuel consumption per unit transported compared to road transport. This shift to rail-based autorack mobility contributes to reduced air pollution and minimized greenhouse gas emissions, supporting sustainable transportation goals.

Future Trends in Autorack Technology for Rail Mobility

Future trends in autorack technology emphasize automation, enhanced safety, and increased capacity to improve rail mobility efficiency. Innovations include sensor integration for real-time monitoring of vehicle status and automated loading systems that reduce dwell time at terminals. Advanced materials and aerodynamic designs also contribute to energy savings and lower carbon emissions in rail transport.

example of autorack in train Infographic

samplerz.com

samplerz.com