A bioreactor in landfill management is an engineered system designed to accelerate the decomposition of organic waste through controlled microbial activity. These structures optimize conditions such as moisture content, temperature, and aeration to enhance the breakdown of biodegradable materials. Data from operational landfills show that bioreactor technology can reduce landfill gas emissions and stabilize waste mass more rapidly compared to traditional methods. One prominent example is the use of anaerobic bioreactors in municipal solid waste landfills, where organic material is broken down in the absence of oxygen to produce landfill gas rich in methane. This methane is then captured and utilized as a renewable energy source, contributing to greenhouse gas mitigation efforts. Studies report that landfill bioreactors increase waste degradation rates by up to 50%, demonstrating their effectiveness in sustainable waste management practices.

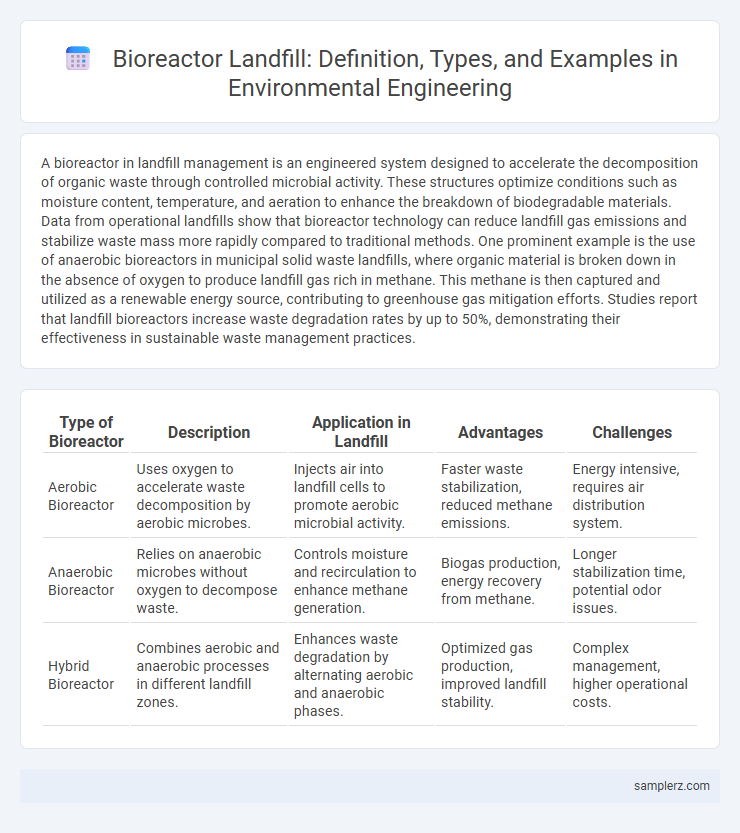

Table of Comparison

| Type of Bioreactor | Description | Application in Landfill | Advantages | Challenges |

|---|---|---|---|---|

| Aerobic Bioreactor | Uses oxygen to accelerate waste decomposition by aerobic microbes. | Injects air into landfill cells to promote aerobic microbial activity. | Faster waste stabilization, reduced methane emissions. | Energy intensive, requires air distribution system. |

| Anaerobic Bioreactor | Relies on anaerobic microbes without oxygen to decompose waste. | Controls moisture and recirculation to enhance methane generation. | Biogas production, energy recovery from methane. | Longer stabilization time, potential odor issues. |

| Hybrid Bioreactor | Combines aerobic and anaerobic processes in different landfill zones. | Enhances waste degradation by alternating aerobic and anaerobic phases. | Optimized gas production, improved landfill stability. | Complex management, higher operational costs. |

Introduction to Landfill Bioreactors

Landfill bioreactors enhance waste decomposition by actively managing moisture and aeration within the landfill, accelerating organic waste stabilization. These engineered systems use controlled addition of liquids and gases to optimize microbial activity, significantly reducing landfill gas emissions and leachate production. Implementation of anaerobic or aerobic bioreactor designs improves landfill sustainability and supports resource recovery initiatives through enhanced biodegradation processes.

Types of Bioreactor Landfills

Types of bioreactor landfills include aerobic, anaerobic, and hybrid systems, each designed to optimize waste decomposition and gas production. Aerobic bioreactors inject air to enhance microbial activity, speeding up organic waste breakdown. Anaerobic bioreactors operate without oxygen, maximizing methane generation for landfill gas recovery, while hybrid systems combine both methods to balance degradation rates and gas collection efficiency.

Leachate Recirculation Systems

Leachate recirculation systems in landfills enhance biodegradation by reintroducing leachate into waste, accelerating microbial activity and stabilizing organic matter. These bioreactors maintain optimal moisture and temperature levels, improving the efficiency of waste decomposition and reducing environmental contamination risks. Effective leachate recirculation reduces landfill lifespan and minimizes greenhouse gas emissions by promoting anaerobic digestion processes.

Aerobic vs. Anaerobic Bioreactors

Aerobic bioreactors in landfills introduce oxygen to accelerate organic waste decomposition, reducing methane emissions and promoting faster stabilization of waste. Anaerobic bioreactors operate without oxygen, fostering microbial activity that produces biogas, primarily methane and carbon dioxide, which can be captured for renewable energy. Both systems enhance landfill management but differ in gas generation, environmental impact, and waste treatment efficiency.

Case Study: Sarasota County Bioreactor Landfill

The Sarasota County Bioreactor Landfill in Florida demonstrates enhanced waste decomposition through controlled liquid addition and leachate recirculation that accelerates microbial activity. This bioreactor landfill achieved a reduction in settling time by approximately 50%, improving space utilization and extending landfill lifespan. Monitoring data showed increased methane production, highlighting its potential for renewable energy recovery while mitigating environmental impacts.

Operational Mechanisms of Landfill Bioreactors

Landfill bioreactors accelerate waste decomposition by actively managing moisture, temperature, and aeration within the waste mass, enhancing microbial activity and methane production. Operational mechanisms involve leachate recirculation systems that maintain optimal moisture levels and gas collection systems to capture biogas for energy recovery. Sensors and control systems monitor environmental parameters, ensuring efficient biodegradation and minimizing environmental impact.

Environmental Benefits of Bioreactor Landfills

Bioreactor landfills accelerate waste decomposition by enhancing microbial activity through controlled moisture and aeration, significantly reducing methane emissions compared to traditional landfills. These systems promote faster stabilization of organic waste, minimizing the production of leachate and its environmental impact on surrounding soil and groundwater. The improved efficiency in waste degradation supports sustainable waste management practices, contributing to lower greenhouse gas emissions and better protection of ecosystems.

Challenges in Bioreactor Landfill Implementation

Bioreactor landfills face significant challenges such as leachate management, which requires effective recirculation systems to prevent groundwater contamination. Maintaining optimal moisture content and temperature is crucial for microbial activity but difficult due to heterogeneous waste composition. Infrastructure costs and regulatory compliance also hinder widespread implementation of bioreactor technology in landfill operations.

Monitoring and Control Technologies

Advanced bioreactors in landfills utilize sensor arrays to continuously monitor parameters such as temperature, pH, and moisture content, optimizing microbial activity for enhanced waste decomposition. Real-time data acquisition enables precise control of leachate recirculation and gas extraction rates, improving landfill stabilization and methane recovery efficiency. Integration of automated control systems reduces environmental risks by maintaining aerobic or anaerobic conditions tailored to specific waste compositions.

Future Trends in Bioreactor Landfill Development

Future trends in bioreactor landfill development include the integration of advanced sensor technologies and real-time data analytics to optimize microbial activity and gas production. Innovations in waste pre-treatment methods, such as hydrothermal processing, enhance biodegradation rates and reduce environmental impact. Emerging designs emphasize closed-loop systems that improve leachate recycling and methane capture efficiency for sustainable waste management.

example of bioreactor in landfill Infographic

samplerz.com

samplerz.com